Ịkwado na ndozi plastik n'ime ụgbọ ala

Ihe

- Ụzọ nrụzi rọba

- Nhọrọ mmezi rọba

- Ndozi plastik site na ịgbado ọkụ

- Jiri teepu Uni-Weld na Fiberflex rụzie ya

- Idozi staples gbajiri agbaji

- Ndozi plastik na gluu ozugbo

- Ndozi plastik nwere resin epoxy nwere akụkụ abụọ

- Ngwa Putty

- A na -eji ihe mbido ete ime ihe dị n'elu tupu itinye akwa ahụ

- Ngwa agba na -agbanwe agbanwe

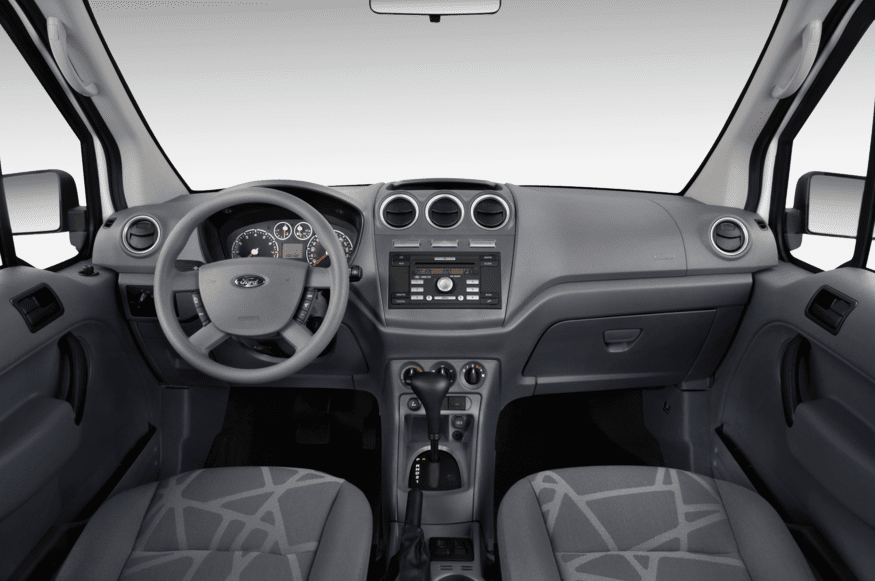

N'ọtụtụ ụgbọ ala ọgbara ọhụrụ, a na-eji plastik dochie akụkụ ọla. Ihe kpatara ya bụ obere arọ nke ụgbọ ala, obere mmanụ ọkụ, corrosion na, n'ezie, ọnụ ala. Mgbe ị na-arụzi akụkụ ụgbọ ala rọba, ọ dị mkpa iburu n'uche akụkụ akụ na ụba nke imezi otu ma ọ bụ ihe ọzọ na ịrụ ọrụ nke plastik mgbe emezichara.

N'ọtụtụ ụgbọ ala ọgbara ọhụrụ, a na-eji plastik dochie akụkụ ọla. Ihe kpatara ya bụ obere arọ nke ụgbọ ala, obere mmanụ ọkụ, corrosion na, n'ezie, ọnụ ala. Mgbe ị na-arụzi akụkụ ụgbọ ala rọba, ọ dị mkpa iburu n'uche akụkụ akụ na ụba nke imezi otu ma ọ bụ ihe ọzọ na ịrụ ọrụ nke plastik mgbe emezichara.

Ụzọ nrụzi rọba

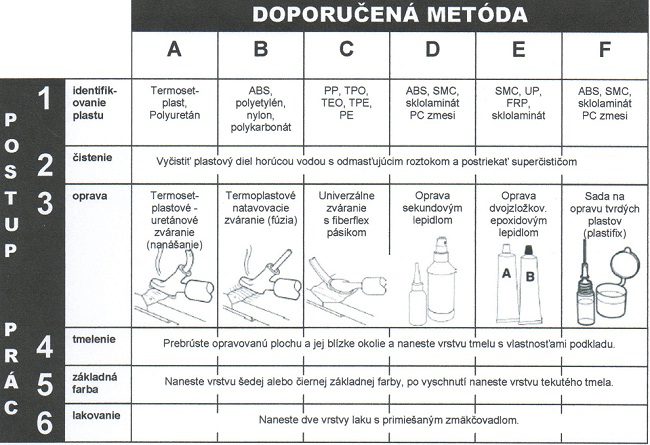

Usoro ọrụ bụ njirimara nke plastik, nhicha, usoro nrụzi n'onwe ya, akara, agba agba, eserese.

Njirimara rọba

Ụzọ kachasị mfe iji chọpụta plastik bụ ịtụgharị ya wee lelee n'ime maka akara ndị nrụpụta. Mgbe ahụ, chọọ akara a na tebụl agbakwunyere (Chart Reference for Plastic Repair) na, n'ihe gbasara ọtụtụ ụzọ nrụzi a tụrụ aro, họrọ nke kacha mma maka gị. Ọ bụrụ na ọ gaghị ekwe omume ịchọpụta plastik site na akara, ọ na-esiri ike ikpebi usoro nrụzi, nke a na-achọ ndị ọkachamara nwere ahụmahụ nke ukwuu n'ọhịa nwere ike ịhọrọ usoro nrụzi kwesịrị ekwesị maka akụkụ ahụ.

Isiokwu Ntụgharị Ntụle plastik

Nhicha ụlọ tupu arụzi

Iji nweta ike nrụzi dị elu na ogologo ndụ ọrụ nke akụkụ a na -arụzi, ọ dị mkpa ka ehichachaa elu ya nke ọma site na mmetọ dị iche iche, ọkachasị n'ebe nrụzi ezubere.

Kwụpụ mba. 1: Jiri ihe nhicha na mmiri sachaa akụkụ abụọ nke akụkụ ahụ wee jiri akwụkwọ ma ọ bụ mgbawa ikuku kpoo ya.

Kwụpụ mba. 2: were akwa nhicha (degreaser) fesaa mpaghara arụziri arụzi ma were akwa kpọrọ nkụ hichaa ya. Na -ehicha akwa ahụ mgbe niile na akụkụ ọhụrụ. Na -ehicha ihe n'otu oge. Usoro a na -ezere ịbanye nsị n'ime akụkụ a ga -asachapụ.

Nhọrọ mmezi rọba

Mmezi overhang

Ọ bụrụ na ekpuchi elu ya, anyị na -eji egbe ọkụ na -arụzi ihe ndị mebiri emebi. Mgbe ị na -ekpo plastik, ọ dị mkpa ka kpoo ya ọkụ kpamkpam. Ezigbo okpomọkụ pụtara ijide egbe ọkụ n'otu akụkụ ruo mgbe akụkụ nke ọzọ dị oke ọkụ nke na enweghị ike ijide elu ya n'aka gị. Mgbe rọba ahụ chara nke ọma, anyị na -eji otu osisi pịa akụkụ ahụ mebiri emebi na ọnọdụ ziri ezi wee dị jụụ ma hichaa ebe ahụ (ị nwere ike iji mmiri ikuku ma ọ bụ akwa mmiri oyi mee ya).

Thermosetting plastics - polyurethanes (PUR, RIM) - bụ plastik na ebe nchekwa, ekele nke ha na-akpaghị aka na-alaghachi n'ọnọdụ mbụ ha mgbe kpo oku na-ekpo ọkụ egbe ma ọ bụ na agba agba.

Mmezi plastik thermosetting sitere na plastik uranium.

Automotive urethane ma ọ bụ PUR bụ ihe na-eguzogide okpomọkụ. Na mmepụta ya, a na-eji mmeghachi omume dị ka nke a na-eji eme ihe mgbe ị na-ejikọta ihe mkpuchi na ihe siri ike - ya bụ, mmiri mmiri 2 ọnụ na otu ihe siri ike na-emepụta na-enweghị ike ịlaghachi n'ọnọdụ mbụ ya. N'ihi nke a, plastik enweghị ike ịgbaze. Ọ gaghị ekwe omume ịgbaze plastik site na welder. Ụzọ a pụrụ ịdabere na ya iji mara ma ọ bụrụ na bompa bụ polyurethane bụ itinye ọnụ na-ekpo ọkụ na-ekpo ọkụ na azụ nke bompa. Ọ bụrụ na ọ bụ urethane, plastik ga-amalite ịgbaze, afụ, na anwụrụ ọkụ (welder kwesịrị ịdị ọkụ nke ukwuu iji mee nke a). Mgbe elu ahụ a kpụrụ akpụ ajụọ oyi, rọba ahụ na-anọgide na-akpachi anya na mmetụ ahụ. Nke a bụ ihe ịrịba ama na okpomọkụ emebiwo nhazi nke ụmụ irighiri ihe dị na plastik. Enwere ike ịrụzi urethanes thermoset n'ụzọ dị mfe site na welder enweghị ikuku, mana nrụzi ahụ ga-abụ nke na-ekpo ọkụ na-ekpo ọkụ karịa ịgbado ọkụ (ịkọpụta mkpanaka na nkwado).

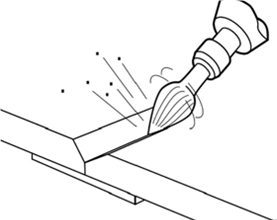

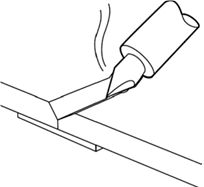

Nkwadebe nke V-grooves na mpaghara mebiri emebi

Anyị na -agbazi ma jiri teepu aluminom kpoo akụkụ ndị mebiri emebi. Maka nnukwu mpaghara, chekwaa mkpọchi mkpakọ. Ịnwekwara ike iji gluu jikọọ akụkụ ahụ (dịka ụdị 2200). N'azụ akụkụ a ga-arụzi, anyị na-egwe ọka V-groove na igwe igwe nri teepu. Anyị enweghị ike iji ọnụ na -ekpo ọkụ kama igwe igwe igwe maka usoro a n'ihi na ihe anaghị ekwe omume. Jiri mpempe akwụkwọ aja kpuchie V-groove (z = 80) ma ọ bụ ọbụlagodi. Site n'ikuku elu, anyị na -enweta oghere ndị ọzọ na mpaghara milled. Ọzọkwa na mpaghara V-groove, wepu varnish ahụ ma mee ka akụkụ nke V-groove dị nro ka mgbanwe dị n'etiti elu na V-groove dị mma.

Itinye mkpanaka n'ime V-uzo

A ga -edobe okpomoku na igwe ịgbado ọkụ site na iji njikwa kwekọrọ na mkpanaka transperent (R1). N'iji mkpanaka polyurethane 5003R1, anyị enwetala eziokwu na ọpụpụ site na akpụkpọ ụkwụ ịgbado ọkụ, mkpanaka ahụ kwesịrị ịpụta na ọnọdụ mmiri mmiri, translucent na -enweghị afụ. Jide akpụkpọ ụkwụ ịgbado ọkụ n'elu ka a ga-agbado ya wee pịa mkpanaka dị n'etiti ya na V-groove na ya. Anyị anaghị ekpo oke ọkụ, mana anyị na -awụnye mkpanaka n'elu ya. Ejikọla ogwe osisi ahụ na bompa. Ka anyị ghara ichefu na urethane anaghị agbaze. Etinyekwala mkpanaka karịa 50 mm n'otu oge. Anyị na -ewepụta mkpara ahụ na akpụkpọ ụkwụ ahụ tupu mkpanaka ahụ a gbazere agbaze dị na ya ajụjụọ, were akpụkpọ ụkwụ dị ọkụ mee ka elu ya dị larịị.

Nkwadebe nke V-grooves n'akụkụ nke ọzọ

Mgbe ịgbado ọkụ na akụkụ azụ jụrụla oyi, megharịa ime V-groove, sanding na ịgbado ọkụ n'akụkụ nke ọzọ.

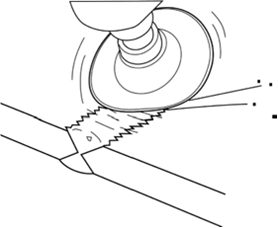

Ị na -egweri weld ahụ ka ọ dị larịị

N'iji akwụkwọ siri ike, wụsa weld na ebe dị larịị. Enweghị ike ịkekọta nkwonkwo urethane nke ọma, yabụ ọ ga -adị mkpa ka etinye akwa mkpuchi ihe n'elu ka a rụzie ya. Wepu obere ihe site na weld site na iji ájá eme ihe ka ihe mkpuchi ahụ wee kpuchie elu ya niile.

Ndozi plastik site na ịgbado ọkụ

Ewezuga urethane, ihe niile bumpers na ọtụtụ plastik ụgbọ ala na-esite na thermoplastics. Nke a pụtara na enwere ike ịgbaze ha mgbe ọkụ. A na-eme akụkụ thermoplastic site n'ịgbaze beads rọba na ịgbanye ihe mmiri mmiri n'ime ihe n'ụdị ebe ha na-ajụ oyi ma sie ike. Nke a pụtara na thermoplastics bụ fusible. Ihe ka ọtụtụ n'ime bumpers emepụtara bụ nke ihe TPO. TPO aghọwo ngwa ngwa a na-ewu ewu maka mmepụta nke ime ime na akụkụ engine. Enwere ike ịgbanye TPO site na iji teknụzụ ngwakọta ma ọ bụ mkpanaka Fibreflex pụrụ iche nke na-eme ka weld dịkwuo ogologo. Ihe nke atọ kachasị ewu ewu bụ Xenoy, nke kacha mma welded.

Nkwadebe nke V-grooves na mpaghara mebiri emebi

Anyị na -agbazi ma jiri teepu aluminom kpoo akụkụ ndị mebiri emebi. Maka nnukwu mpaghara, chekwaa ha na mkpakọ mkpakọ. Anyị nwekwara ike jikọta ụdị ya na ụdị nke abụọ 2200. N'azụ akụkụ arụziri arụzi, anyị na-egwe ọka V-groove na igwe igwe nri teepu. Maka usoro a, anyị nwere ike iji ọnụ na -ekpo ọkụ kama igwe igwe igwe, ebe ihe a na -emegharị emegharị. Wepụ agba gburugburu nrụzi ahụ e mere atụmatụ site na iji aja aka ma wepu chamfer n'etiti elu na V-groove.

Ịgwakọta isi na isi ihe

Anyị debere okpomọkụ na igwe ịgbado ọkụ ka o kwekọọ na mkpanaka ịgbado ọkụ ahọpụtara, nke anyị kpebiri n'oge usoro njirimara. N'ọtụtụ oge, mkpanaka weld na mpe mpe akwa kwesịrị ịpụta dị ọcha na enweghị agba. Nanị otu ga -abụ nylon, nke na -atụgharị translucent gaa na agba aja aja. Debe akpụkpọ ụkwụ ịgbado ọkụ na ntọala wee jiri nwayọ tinye mkpanaka ahụ n'ime V-groove. Anyị na-eji nwayọ amanye mkpanaka n'ihu anyị ka anyị nwee ike hụ n'azụ anyị oghere nwere ụdị V nke ihe a jupụtara. Oke mkpanaka ịgbado ọkụ 50 mm n'otu usoro. Anyị na -ewepụta mkpara ahụ na akpụkpọ ụkwụ ahụ, tupu mkpanaka ahụ ajụa oyi, jiri nlezianya kpalie ma jikọta ihe ndị ahụ ọnụ. Ngwá ọrụ dị mma bụ nsọtụ akpụkpọ ụkwụ ahụ, nke anyị na -ejikọ ọnụ ya n'ime ihe dị n'okpuru wee jikọta ha. Mee ka elu ya dị nro jiri ọnụ dị ọkụ. Hapụ ọnụ ahụ ọkụ n'oge usoro agwakọta.

Nkwadebe V-uzo na ịgbado ọkụ n'akụkụ nke ọzọ

Mgbe akụkụ azụ ahụ jụrụ oyi nke ọma, anyị na-emegharị usoro ịkwadebe oghere dị n'ụdị V, na-egweri ma na-agbado n'ihu.

Welds na -egweri

N'iji akwụkwọ siri ike, wụsa weld na ebe dị larịị. Wepu obere ihe site na weld site na iji ájá eme ihe ka ihe mkpuchi ahụ wee kpuchie elu ya niile.

Jiri teepu Uni-Weld na Fiberflex rụzie ya

Mgbanaka Welding Universal bụ ihe ndozi pụrụ iche nke enwere ike itinye na rọba ọ bụla. Ọ bụghị mkpanaka ịgbado ọkụ n'ezie, ọ bụ karịa ụdị gluu na-ekpo ọkụ. Mgbe anyị na-arụzi osisi a, anyị ga-eji okpomọkụ nke welder, kama maka nrapado ya. Mkpanaka dị ka eriri Fiberflex nwere nhazi siri ike. A na-eji carbon na fiberglass mee ka ọ dịkwuo ike maka inwekwu ike. Fiberflex bụ ihe ngwọta kachasị mma maka nrụzi TPO (nakwa TEO, PP/EPDM) i.e. ihe ndị a na-ejikarị eme ihe maka bumpers. Enwere ike iji Fiberflex rụkwaa ụdị plastik niile. Ọ nwere ike ịrapara na urethane yana xenos. Ọ bụrụ na anyị ejighị n'aka ihe plastik anyị na-agbado, naanị anyị na-eji Fiberflex. Uru ọzọ nke Fiberflex bụ fusibility ya. Ọdịdị dị mma nke weld na-ebelata ojiji nke sealant.

Nkwadebe nke V-grooves na mpaghara mebiri emebi

Anyị na-agbazi ma jiri teepu aluminom mechie akụkụ ndị mebiri emebi, dozie ya na mkpakọ mkpakọ na mpaghara buru ibu. I nwekwara ike jikọta ụdị nke abụọ 2200. obosara nke ọkwa V nwere kwesịrị ịbụ 25-30 mm. Ọ dị ezigbo mkpa iji ájá kpuchie ájá elu karịa V-groove iji nweta mpaghara ọzọ na obere oghere. Ọ bụrụ na anyị na -eji sander vibration rotary maka egweri, anyị ga -ebelata ọsọ ka ọ dịkarịa ala iji gbochie agbaze ihe nke thermoplastics na -emetụta. N'iji akwụkwọ aja (z = 60), wepu varnish ahụ site na elu ya niile ka ọ rụzie ma belata ihu n'etiti V-groove na elu. Nke a na -enye anyị ohere ịgbasa nke ọma wee pịa teepu Fiberflex na saịtị nrụzi.

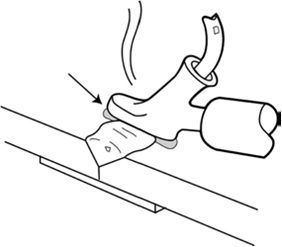

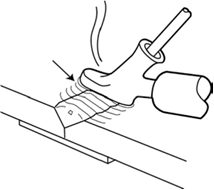

Fiberflex teepu agbaze

Debe igwe ịgbado ọkụ na oke okpomọkụ nwere ike dochie ya ma were akwa na -agbaze dochie akpụkpọ ụkwụ ịgbado ọkụ (na -enweghị tube ntuziaka). Ọ kacha mma ihichapụ otu akụkụ nke eriri Fiberflex ya na ebe dị ọkụ iji gbazee ya ma tinye ya ozugbo na mkpụrụ ahụ. Kewapụ akụkụ glued na nsọtụ efere dị ọkụ site na eriri ndị ọzọ. Mgbe ahụ gbazee warara ahụ na V-groove. Anyị anaghị anwa ịgwakọta isi ihe na Fiberflex. Usoro a yiri usoro gluu na -ekpo ọkụ.

Nkwadebe nke V-grooves na ịgbado ọkụ nke facade

Mgbe Fiberflex dị n'azụ jụrụ oyi (anyị nwekwara ike jiri mmiri oyi mee ka usoro ahụ dị ngwa), megharịa usoro ịcha, ighe na ịgbado ọkụ. I nwekwara ike tinye akwa Fiberflex ka ọ na -egwe nke ọma.

Egweri

Ozugbo ịgbado ọkụ Fiberflex jụrụ oyi, bido site n'ikuku (z = 80) na ngwa ngwa. Jiri akwụkwọ akpụkpọ anụ mechie usoro ịcha aja (z = 320). A ga -eji ihe nrịbama mechie mmejọ niile.

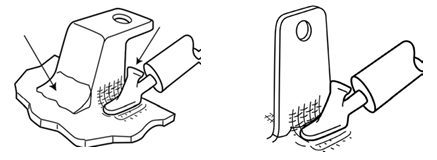

Idozi staples gbajiri agbaji

Ọtụtụ TEO bumpers nwere braket nke kwesịrị ịdị na-agbanwe iji mee ka nrụnye dị mfe. Enwere ike imezi ihe owuwu a nke ọma site na igwe igwe anaghị agba nchara na fiberflex. Nke mbụ, jiri sander rotary mee ka elu ya dị nro. Site na igwe anaghị agba nchara, anyị ga-ebipụ akụkụ nke dị mma maka ijikọ njikwa na isi n'akụkụ abụọ. N'iji ọnụ na-ekpo ọkụ, pịa mpempe akwụkwọ ndị a n'ime plastik. Mgbe agbazechara ma mee ka ọ dị jụụ, jiri akwụkwọ mee ka ájá kpuchie elu ya iji wepụ ihe ndị na-egbuke egbuke. Tinye eriri Fiberflex n'elu a na-agwọ ya. Site na nrụzi a, ntupu na-ekwe nkwa ike na mgbanwe, na eriri eriri bụ naanị mkpuchi ịchọ mma.

Ndozi plastik na gluu ozugbo

Ebe ọ bụ na nrapado nke abụọ na -etolite agbụ siri ike, a na -ahọrọ ha maka ịrụzi plastik dịka ABS, PC, SMC, plastik siri ike. Ha dịkwa mma maka akụkụ njikọta ntụpọ site na idozi ha tupu ịgbado ọkụ.

Ndozi ngwa ngwa nke mgbawa

Ihe kacha mkpa isonyere akụkụ bụ iji fesaa akụkụ ahụ ka ejikọtara ya na onye na -eme ihe. Anyị na -etinye ma jikọọ akụkụ ahụ. Jiri teepu aluminom 6481. Maka akụkụ buru ibu, jiri mkpọchi iji hụ na edobere akụkụ ndị ahụ n'oge njikọta. Debe obere gluu ozugbo iji mejupụta mgbape. A na -enweta nsonaazụ kacha mma site na opekempe kacha nta etinyere na nkwonkwo. Mmanya ahụ dị gịrịgịrị iji banye na mgbape ahụ. Fesa mgbakwunye nke onye na -eme ihe iji mezue usoro a na oghere pere mpe.

Na -ejuputa oghere na oghere

Anyị na -eji teepu aluminom emechi oghere na ala. Kwadebe V-notch gburugburu gburugburu oghere ahụ na aja ya na mpaghara gbara ya gburugburu site na ịfụfụ uzuzu. Fesa mpaghara a ga -eji nwayọ rụzie ya. Jupụta oghere na putty ma tinye ntụtụ ole na ole nke gluu. Anyị na -ahazi ma pịa gluu n'ime ngwa nchacha jiri ngwa dị nkọ. Mgbe sekọnd 5-10 gachara, tinye obere ọkụ nke activator. Enwere ike ịkpụcha aja ya ozugbo wee gwuo ala.

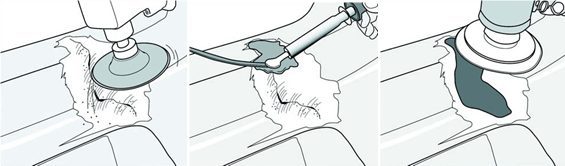

Ndozi plastik nwere resin epoxy nwere akụkụ abụọ

Aja n'azụ ebe a rụziri ya na akwụkwọ aja (z = 50 ma ọ bụ karịa). Ọkpụkpụ miri emi mgbe egwerichara bụ ezigbo ntọala maka njikọ siri ike. Mgbe ahụ jiri mpempe akwụkwọ mee ka ájá dị n'elu ala (z = 80), nke na-enyekwa aka na njikọ dị mma. Ọ bụrụ na eji TEO, TPO ma ọ bụ PP ihe, anyị ga-eji 1060FP ụdị nkwado nrapado. Gbasaa ngwaahịa ahụ na ahịhịa n'elu aja aja wee hapụ nkụ. Anyị na-amanye fiberglass n'ogologo dum nke akụkụ ahụ mebiri emebi. Ọ bụrụ na akụkụ nke SMC na-apịaji n'elu mgbape yana akụkụ ọzọ fọdụrụ nke SMC mekwara, hụ na akụkụ a na-agafe agafe gafere ebe mmebi na ntụziaka ọ bụla ma ọ dịkarịa ala 0,5mm. Anyị ga-ahọrọ ihe nrapado nwere akụkụ abụọ dabara adaba nke kacha yie akụkụ a ga-ejigide:

- Filler 2000 Flex (isi awọ) na -agbanwe agbanwe

- 2010 Ihe na-agbanwe agbanwe ọkara na-agbanwe agbanwe (ọbara ọbara)

- 2020 SMC Hardset Filler (Grey) siri ike

- 2021 Ihe siri ike (edo edo) siri ike

Gwakọta epoxy zuru oke. Tinye akwa iji kpuchie teepu na eriri ma hapụ ya ka ọ kpọọ nkụ ma ọ dịkarịa ala minit 15. Na SMC, anyị na -emepụta akwa gluu maka mpempe nkwado, nke anyị na -etinyezi n'ime akwa a kwadebere. N'okwu a, ka gluu kpoo ma ọ dịkarịa ala minit 20. Jiri akwụkwọ (z = 50) kụọ ihu akụkụ ahụ mebiri emebi ma kụọ aja V-groove na mgbape. Ka ogologo a na -abawanye na oghere a, njikọ ahụ na -esikwu ike. Debe ọnụ ọnụ oghere V, were akwụkwọ jiri aja kpuchie elu ya (z = 80). Gwakọta ma tinye nrapado nke nrapado epoxy wee kpụzie ya ka ọ gafee n'elu elu gbara ya gburugburu. Ka akpọọ nkụ ma ọ dịkarịa ala nkeji iri abụọ. Naanị mgbe ahụ ka anyị ga -amalite egweri. N'iji SMC, anyị na-etinye iberibe akwa fiberglass dị iche iche n'ime V-uzo na n'etiti akwa nrapado n'otu n'otu. N'iji igwe na -agbagharị agbagharị, anyị na -eji nlezianya pịa akwa ahụ na gluu wee chụpụ afụ ikuku na -achọghị. Anyị na -eji mpempe akwụkwọ edozie elu a mịrị amị (z = 20, z = 80).

Ngwa Putty

Aja elu na -sanded keadighi rarii akwụkwọ. Kwadebe obere V-groove na saịtị mmebi. A ga -ewepụrịrị akụkụ niile na -egbu maramara tupu itinye ihe nrachi ahụ, ma ọ bụghị na nrapado dị mma agaghị eme. Ọ bụrụ na ihe ahụ bụ polyolefin (PP, PE, TEO ma ọ bụ plastik sitere na mmanụ TPO), anyị na-etinye nrapado nkwado nke nwere ikuku nke ọma. Anyị na -ahọrọ ihe mkpuchi epoxy dabara adaba nke dabara na mgbanwe nke isi ihe. Ọ bụrụ na ọ na-agbanwe agbanwe, jiri 2000 Flex Filler 2 ma ọ bụ Adhesive Semi-rọba 2010. Ọ bụrụ na ọ siri ike, jiri 2020 SMC Rigid Kit ma ọ bụ 2021 Rigid Filler. Gwakọta ego edepụtara maka ihe mkpuchi epoxy. Anyị ga -emepụta akwa sealant dị elu karịa elu gbara ya gburugburu. Anyị anaghị ebido ikpuchi akpụkpọ ụkwụ tupu mgbe nkeji iri abụọ gachara, maka ịkpụ aja anyị na -eji akwụkwọ nwere oke ọka (z = 20, mgbe ahụ 80).

A na -eji ihe mbido ete ime ihe dị n'elu tupu itinye akwa ahụ

Ọ bụrụ na ihe ahụ bụ ọkara-olefin (TEO, TPO ma ọ bụ PP), tinye nrapado na-akwado akụkụ niile esere dịka usoro edepụtara na akara ngwaahịa. N'elu nke a ga -arụzi, tinye isi ntụ ntụ nke isi awọ ma ọ bụ nke ojii na obere mkpa. Mgbe ihichachara, were akwụkwọ ájá kpuchie elu ya (z = 320-400).

Ngwa agba na -agbanwe agbanwe

Mgbe ị kpuchiri isi ala, fụpụ uzuzu, tinye ngwaahịa na -eme ka nchacha niile dị n'elu ga -arụzi. Gwakọta ngwaahịa ahụ na agba a na -eteghị ete. Mgbe ahụ, anyị na -agwakọta agba ahụ na ihe dị gịrịgịrị, na -emetụta akụkụ ahụ dum nke panel ahụ dị ka ntuziaka nke onye nrụpụta si kwuo, zere ịgbasa ntụpọ. Iji nweta nlele nke akụkụ plastik, anyị na -eji ịgba ihe mgbochi ojii na -agbanwe agbanwe.

Mgbe ị na -arụzi plastik ụgbọ ala, anyị ga -eburu n'uche, nke mbụ, akụkụ ọrụaka nke ga -ekwe omume nrụzi yana ntule nrụzi emere site na echiche akụ na ụba. Mgbe ụfọdụ ọ na -adị ngwa ngwa, dịkwa mfe ma dịkwa ọnụ ala karịa ịzụta akụkụ rọbaị eji eme ihe n'ọnọdụ dị mma.