Mmanụ ụgbọala njem - Mgbapụta Mgbapụta

Ihe

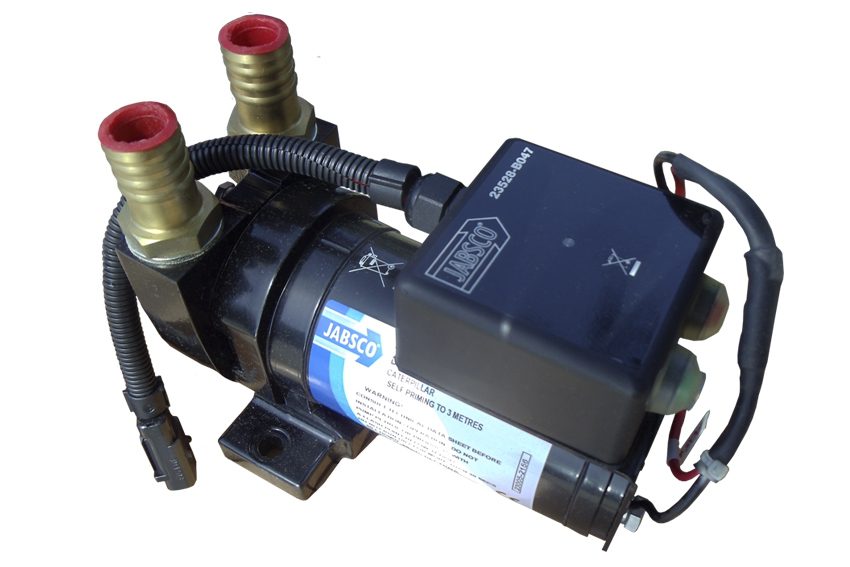

Ihe mgbapụta mmanụ ọkụ ma ọ bụ mgbapụta mmanụ ọkụ bụ akụkụ nke sekit mmanụ ụgbọala nke na-ebufe mmanụ site na tank ahụ gaa n'akụkụ ndị ọzọ nke mmanụ ụgbọala. Taa, ndị a bụ tumadi injection nfuli (elu mgbali) - kpọmkwem injection engine. Na ochie engines (petrol indirect injection) ọ bụ a kpọmkwem injector ma ọ bụ ọbụna na ndị agadi ụgbọala a carburetor (float ụlọ).

Ihe mgbapụta mmanụ ọkụ ma ọ bụ mgbapụta mmanụ ọkụ bụ akụkụ nke sekit mmanụ ụgbọala nke na-ebufe mmanụ site na tank ahụ gaa n'akụkụ ndị ọzọ nke mmanụ ụgbọala. Taa, ndị a bụ tumadi injection nfuli (elu mgbali) - kpọmkwem injection engine. Na ochie engines (petrol indirect injection) ọ bụ a kpọmkwem injector ma ọ bụ ọbụna na ndị agadi ụgbọala a carburetor (float ụlọ).

Enwere ike ịkwọfe mgbapụta mmanụ n'ime ụgbọ ala n'ụzọ igwe, hydraulic ma ọ bụ eletrik.

Mgbampụta mmanụ ọkụ na-arụ n'ọrụ

Diaphragm mgbapụta

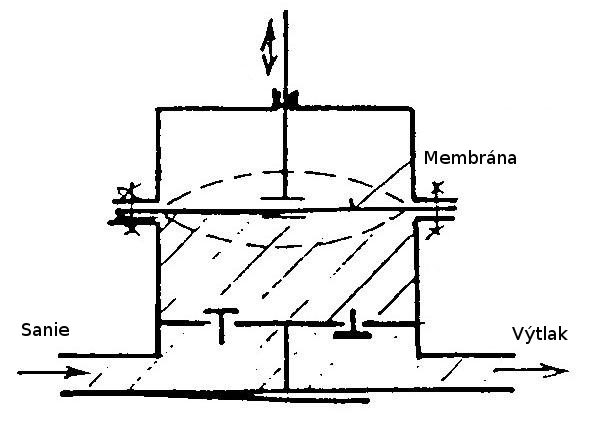

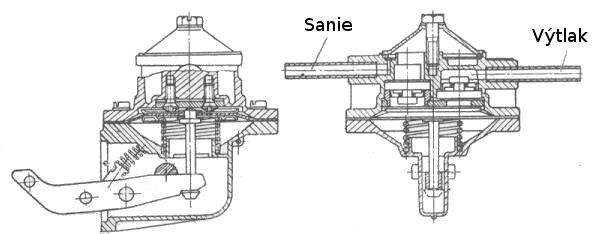

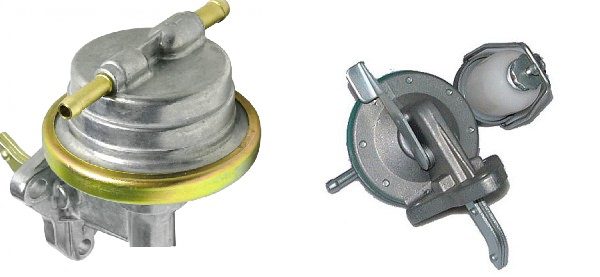

Igwe mmanụ ụgbọ ala ochie nke nwere carburetors na-ejikarị mgbapụta diaphragm (nrụpụ ikike 0,02 ruo 0,03 MPa), nke usoro eccentric na-achịkwa (pusher, lever na eccentric). Mgbe carburetor jupụtara na mmanụ ọkụ nke ọma, valvụ agịga nke na-ese n'elu mmiri na-emechi, valvụ mgbapụta mgbapụta na-emepe, na eriri nkwụsị na-anọgide na-arụ ọrụ iji jide diaphragm na oke ọnọdụ nke usoro ahụ. Akwụsịla njem mmanụ ụgbọala. Ọbụlagodi na usoro eccentric ka na-agba ọsọ (ọbụlagodi mgbe injin ahụ na-agba ọsọ), mmiri nke na-edozi strok mwepu nke diaphragm mgbapụta na-anọgide na-agbakọ. Mgbe valvụ agịga na-emepe, nrụgide dị na eriri mgbapụta mgbapụta na-adaba, na diaphragm, nke mmiri na-akwali, na-eme ka ọkpụkpụ na-agbapụta, nke na-adabere ọzọ na pusher ma ọ bụ lever nke usoro nchịkwa eccentric, nke na-ejikọta mmiri na mmiri. diaphragm ma na-aṅụ mmanụ ụgbọala si na tank n'ime ụlọ ise n'elu mmiri.

gia mgbapụta

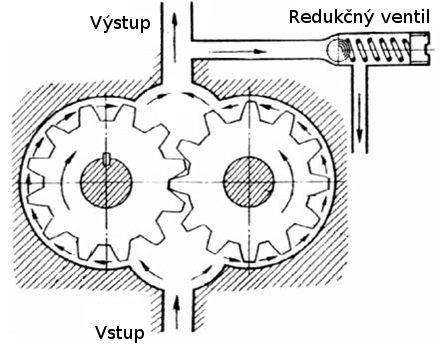

A nwekwara ike ịkwọpụta mgbapụta gia. Ọ dị ma ọ bụ ozugbo na mgbapụta nrụgide dị elu, ebe ọ na-ekerịta ụgbọala na ya, ma ọ bụ dị iche iche ma nwee ụgbọala nke ya. A na-ebugharị mgbapụta gia n'ụzọ igwe site na njigide, gia ma ọ bụ eriri ezé. Igwe mgbapụta gia dị mfe, obere nha, ịdị arọ dị arọ na nke a pụrụ ịdabere na ya nke ukwuu. Na-emekarị, a na-eji mgbapụta gia dị n'ime, nke, n'ihi nhazi pụrụ iche, anaghị achọ ihe mkpuchi ọzọ iji mechie oghere onye ọ bụla (ụlọ) n'etiti ezé na oghere dị n'etiti ezé. Ndabere bụ ngwa abụọ ejikọtara ọnụ na-atụgharị n'akụkụ dị iche. Ha na-ebufe mmanụ ọkụ n'etiti tines si n'akụkụ nsị gaa n'akụkụ nrụgide. Ebe kọntaktị dị n'etiti wiil ndị ahụ na-egbochi nlọghachi mmanụ. A na-ejikọta wheel wheel nke dị n'ime na igwe eji arụ ọrụ (engine na-ebugharị) nke na-ebugharị wheel gia dị n'ime. Ezé ahụ na-etolite ụlọ njem mechiri emechi nke na-agbada na cyclically ma na-abawanye. A na-ejikọta ọnụ ụlọ ndị na-ebuwanye ibu na oghere ntinye (suction), ọnụ ụlọ mbelata na-ejikọta ya na oghere (ịgbapụta). Mgbapu nke nwere igbe gia dị n'ime na-arụ ọrụ na nrụgide mwepu ruru 0,65 MPa. Ọsọ nke mgbapụta ahụ, ya mere ọnụ ọgụgụ mmanụ a na-ebufe, dabere na ọsọ nke engine na ya mere a na-achịkwa ya site na valvụ trotul n'akụkụ mmiri ma ọ bụ valve enyemaka nrụgide n'akụkụ nrụgide.

Nfuli mmanụ ọkụ na-ebu ọkụ eletrik

Site na ọnọdụ, a na-ekewa ha na:

- nfuli n'ahịrị,

- nfuli na mmanụ ụgbọala tank (na-tank).

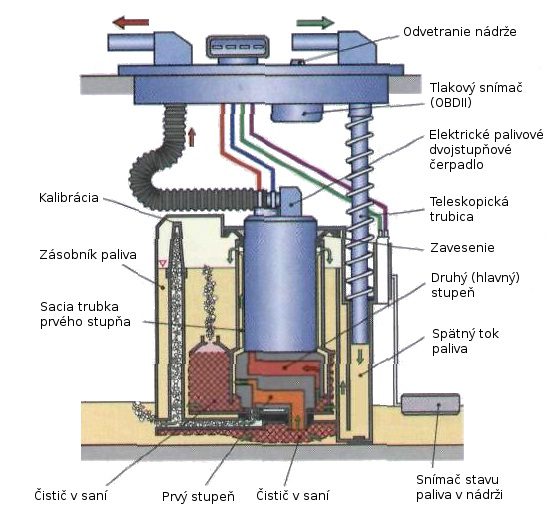

In-Line pụtara na mgbapụta nwere ike ịnọ n'ebe ọ bụla na eriri mmanụ ala dị ala. Uru dị mfe ndochi-nkwado na ihe omume nke mmebi, mwepu bụ mkpa maka ebe kwesịrị ekwesị na nchekwa na ihe omume nke mmebi - mmanụ ụgbọala na-agbapụta. The submersible mgbapụta (In-Tank) bụ ihe mbughari nke mmanụ ụgbọala tank. A na-agbanye ya n'elu tank ma na-abụkarị akụkụ nke modul mmanụ ọkụ, nke gụnyere, dịka ọmụmaatụ, ihe nzacha mmanụ, ihe nkedo na-ekpuchi mmiri na ihe mmetụta mmanụ ọkụ.

Igwe ọkụ ọkụ eletrik na-adịkarị na tank mmanụ. Ọ na-ewe mmanụ ọkụ site na tank ma na-enye ya na mgbapụta nrụgide dị elu (injections kpọmkwem) ma ọ bụ ndị injectors. Ọ ghaghị ijide n'aka na, ọbụlagodi n'ọnọdụ ndị dị oke njọ (arụ ọrụ na-emeghe oghere na okpomọkụ dị n'èzí), afụ adịghị etolite na eriri ọkọnọ mmanụ n'ihi nnukwu oghere. N'ihi ya, e kwesịghị inwe engine malfunctions n'ihi ọdịdị nke mmanụ ụgbọala egosipụta. A na-ekuru ikuku afụ azụ na tank mmanụ site na ikuku mgbapụta. A na-arụ ọrụ mgbapụta ọkụ eletrik mgbe agbanyere ọkụ (ma ọ bụ meghere ọnụ ụzọ onye ọkwọ ụgbọala). Mgbapụta ahụ na-agba ọsọ maka ihe dịka 2 sekọnd ma na-ewulite oke nrụgide na eriri mmanụ. N'oge kpo oku, n'ihe banyere engines dizel, a na-agbanyụ mgbapụta ahụ ka ọ ghara ibuba batrị ahụ n'enweghị isi. Igwe mgbapụta ahụ na-amalite ọzọ ozugbo injin malitere. Enwere ike ijikọ nfuli mmanụ ọkụ ọkụ eletrik na igwe immobilizer ma ọ bụ sistemụ mkpu ma na-achịkwa ya site na njikwa njikwa. Ya mere, njikwa njikwa na-egbochi ịgbalite (nnọọ voltaji) nke mgbapụta mmanụ ọkụ ma ọ bụrụ na ejighi ikike eji ụgbọ ala eme ihe.

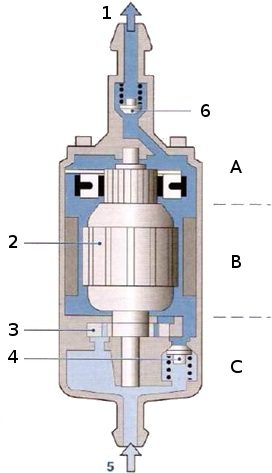

Igwe ọkụ ọkụ eletrik nwere akụkụ atọ:

- moto eletriki,

- sam nasos,

- njikọ mkpuchi.

Ihe mkpuchi njikọ nwere njikọ eletrik arụnyere na njikọ maka ịgbanye eriri mmanụ ọkụ. Ọ na-agụnye valvụ na-adịghị alaghachi azụ nke na-edobe mmanụ dizel na eriri mmanụ ọbụna mgbe agbanyụrụ mmanụ ọkụ.

N'ihe gbasara imewe, anyị na-ekewa nfuli mmanụ ọkụ n'ime:

- eze

- centrifugal (ya na ọwa akụkụ),

- ịghasa,

- nku.

Gear mgbapụta

Igwe mgbapụta gia na-akpụ akpụ na-akpụ akpụ yiri mgbampụ ihe eji arụ ọrụ. A na-ejikọta wheel mpụta dị n'ime ya na moto eletrik nke na-ebugharị wheel dị n'ime.

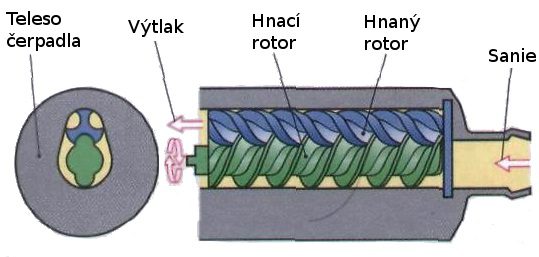

Mgbapụta mgbapụta

N'ụdị mgbapụta a, a na-amịnye mmanụ ọkụ site na ụzọ rotors helical gear na-agbanwe agbanwe. Ndị rotors na-eji obere egwuregwu dị n'akụkụ eme ihe ma na-etinye ogologo oge na mkpuchi mgbapụta. Ntughari ntụgharị nke ndị rotors nwere ezé na-emepụta ohere mbufe olu na-agbanwe nke ọma na-aga nke ọma na axial direction ka rotors na-atụgharị. N'akụkụ ebe a na-abanye mmanụ ụgbọala, ohere njem na-abawanye, na mpaghara ebe a na-emepụta ihe, ọ na-ebelata, nke na-emepụta nrụgide nkwụsị ruo 0,4 MPa. N'ihi nhazi ya, a na-ejikarị screw pump dị ka mgbapụta na-asọpụta.

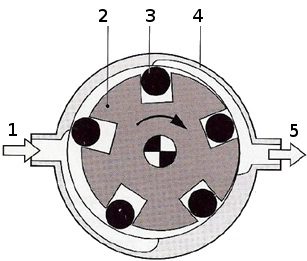

Vane rola mgbapụta

A na-etinye rotor (disk) a na-agbanye n'ike n'ime oghere mgbapụta, nke nwere radial grooves gburugburu gburugburu ya. N'ime oghere ndị ahụ, a na-etinye rollers nwere ike ịwụgharị, na-eme ka a na-akpọ nku rotor. Mgbe ọ na-atụgharị, a na-emepụta ike centrifugal, na-agbanye rollers megide n'ime ụlọ mgbapụta ahụ. Ụzọ nke ọ bụla na-eduzi otu rola n'efu, rollers na-arụ ọrụ dị ka akara mgbasa ozi. A na-emepụta oghere mechiri emechi (ụlọ) n'etiti rollers abụọ na orbit. Oghere ndị a na-abawanye cyclically (mmanụ ọkụ na-amịkọrọ) na mbelata (wepụrụ na mmanụ ụgbọala). Ya mere, a na-ebufe mmanụ ọkụ site na ntinye (inweta) n'ọdụ ụgbọ mmiri n'ọdụ ụgbọ mmiri (outlet). Igwe mgbapụta vane na-enye nrụgide mwepu nke ruru 0,65 MPa. A na-ejikarị mgbapụta igwe eletrik eme ihe n'ụgbọ ala ndị njem na ụgbọ ala azụmahịa. N'ihi nhazi ya, ọ dị mma maka iji ya dị ka mgbapụta in-tank ma dị kpọmkwem na tank.

A - njikọ okpu, B - moto eletriki, C - ihe mgbapụta, 1 - ntinye, nkwụsị, 2 - armature moto, 3 - ihe mgbapụta, 4 - nkwụsị nrụgide, 5 - ntinye, mmiri, 6 - valvụ nlele.

1 - mmiri ara ehi, 2 - rotor, 3 - roller, 4 - efere ntọala, 5 - ntinye, nkwụsị.

Centrifugal mgbapụta

A na-etinye rotor na agụba n'ime ụlọ mgbapụta, nke na-ebugharị mmanụ ọkụ site na etiti gaa na gburugburu site na ntụgharị na ihe na-esote nke ndị agha centrifugal. Nrụgide na ọwa nrụgide n'akụkụ na-abawanye na-aga n'ihu, ya bụ. ihe fọrọ nke nta ka ọ bụrụ enweghị mgbanwe (pulsations) wee rute 0,2 MPa. A na-eji ụdị mgbapụta a dị ka ọkwa mbụ (tupu ogbo) n'ihe gbasara mgbapụta okpukpu abụọ iji mepụta nrụgide maka ịkwanye mmanụ ọkụ. N'ihe banyere nrụnye nke kwụ ọtọ, a na-eji mgbapụta centrifugal nwere ọnụ ọgụgụ dị ukwuu nke rotor blades, nke na-enye nrụgide nkwụsị ruo 0,4 MPa.

Mgbapụta mmanụ ọkụ nke okpukpu abụọ

Na omume, ị nwekwara ike ịhụ mgbapụta mmanụ ọkụ abụọ. Usoro a na-ejikọta ụdị nfuli dị iche iche n'ime otu mgbapụta mmanụ ọkụ. Oge mbụ nke mgbapụta mmanụ ọkụ na-enwekarị obere mgbapụta centrifugal nke na-adọta mmanụ ọkụ ma na-emepụta ntakịrị nrụgide, si otú ahụ na-ekpochapụ mmanụ ọkụ. A na-ewebata isi nke mgbapụta mgbapụta dị ala nke ọkwa mbụ n'ime ntinye (suction) nke mgbapụta nke abụọ na nrụgide dị elu. Nke abụọ - a na-ejikarị mgbapụta isi, na mgbe ọ na-apụ apụ, a na-emepụta nrụgide mmanụ dị mkpa maka usoro mmanụ ọkụ. N'etiti nfuli (mwepu nke 1st mgbapụta na mmiri nke 2nd mgbapụta) e nwere a wuru n'ime overpressure valvụ iji gbochie hydraulic ibu ibu nke isi mmanụ ụgbọala.

Igwe nfuli mmiri na-ebugharị hydraulic

Ụdị mgbapụta a na-ejikarị eme ihe na mgbagwoju anya - tankị mmanụ ọkụ. Nke a bụ n'ihi na n'ime tankị gbawara agbawa, ọ nwere ike ime na mgbe a na-agbanye mmanụ ọkụ (na nkwụsị) mmanụ ọkụ nwere ike ịfefe n'ebe ndị na-adịghị agafe nke mgbapụta mmanụ ọkụ, ya mere ọ na-adịkarị mkpa ịnyefe mmanụ site n'otu akụkụ nke tank ahụ gaa na nke ọzọ. . Maka nke a, dịka ọmụmaatụ, mgbapụta ejector. Ngwunye mmanụ na-esi na mmanụ ọkụ eletrik na-adọta mmanụ si n'akụkụ ọnụ ụlọ nke tank mmanụ site na ejector nozzle wee bufee ya n'ihu na tankị mbufe.

Ngwa mgbapụta mmanụ ụgbọala

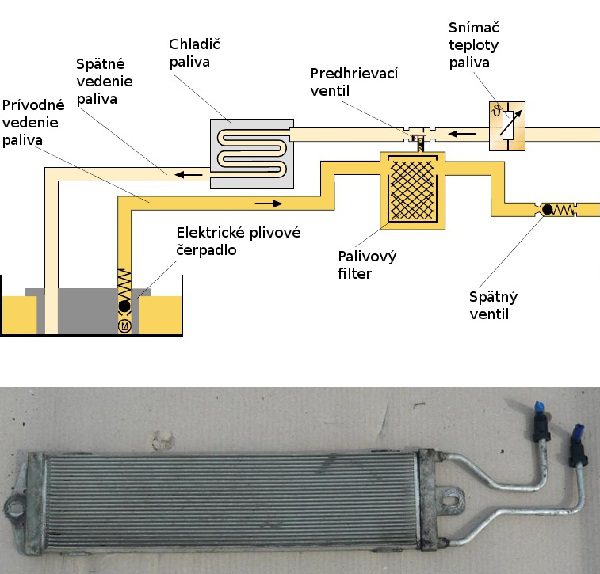

Mmanụ ụgbọala jụrụ oyi

Na PD na usoro ịgbanye ụgbọ okporo ígwè nkịtị, mmanụ a na-emefu nwere ike iru okpomọkụ dị ịrịba ama n'ihi nrụgide dị elu, ya mere ọ dị mkpa iji kpoo mmanụ a tupu ịlaghachi na tank mmanụ. Mmanụ na-ekpo ọkụ nke ukwuu ịlaghachi na tank mmanụ nwere ike imebi ma tank na ihe mmetụta ọkwa mmanụ. A na-eme ka mmanụ ọkụ dị mma na ngwa nju oyi nke dị n'okpuru ala ụgbọ ala. Igwe nju oyi nke mmanụ ọkụ nwere usoro ọwa ogologo oge na-eduzi mmanụ ọkụ azụtara na-esi na ya na-aga. A na-eme ka radiator n'onwe ya dị jụụ site na ikuku nke na-erugharị gburugburu radiator.

valvụ mkpochapụ, ite carbon arụ ọrụ

Mmanụ ụgbọala bụ mmiri mmiri na-agbanwe agbanwe nke ukwuu, mgbe a na-awụsa ya na tank ma gafere na mgbapụta, vapors petrol na afụ. Iji gbochie vapors mmanụ ndị a ka ọ ghara ịpụ na tankị na akụrụngwa ngwakọta, a na-eji usoro mmanụ mechiri emechi nke nwere karama carbon arụ ọrụ. Vapors mmanụ ụgbọala na-etolite n'oge a na-arụ ọrụ, kamakwa mgbe agbanyụrụ injin ahụ, enweghị ike ịgbapụ ozugbo banye na gburugburu ebe obibi, mana a na-ejide ya ma kpochaa ya site na akpa unyi na-arụ ọrụ. Carbon na-arụ ọrụ nwere nnukwu mpaghara (1 gram ihe dịka 1000 m) n'ihi ọdịdị ya na-adịghị mma.2) nke na-ejide mmanụ ụgbọala - mmanụ ụgbọala. Mgbe engine na-agba ọsọ, a na-emepụta nrụgide na-adịghị mma site na eriri dị mkpa nke na-esi na ntinye engine pụta. N'ihi oghere ahụ, akụkụ nke ikuku oriri na-esi na akpa mmiri na-esi na akpa carbon arụ ọrụ. A na-amịpụta hydrocarbons ndị echekwara, na mmanụ a na-amịkọrọ na-amịkọrọ na-abanyeghachi n'ime tank site na valvụ mweghachi. Ọrụ ahụ, n'ezie, na-achịkwa njikwa njikwa.