N'azụ axle MAZ

Ihe

Ndozi nke axle azụ MAZ bụ iji dochie akụkụ ndị eyighị ma ọ bụ mebiri emebi. Nhazi nke azụ azụ na-enye ohere ka arụzi ọtụtụ nrụzi na-ewepụghị ya na ụgbọ ala.

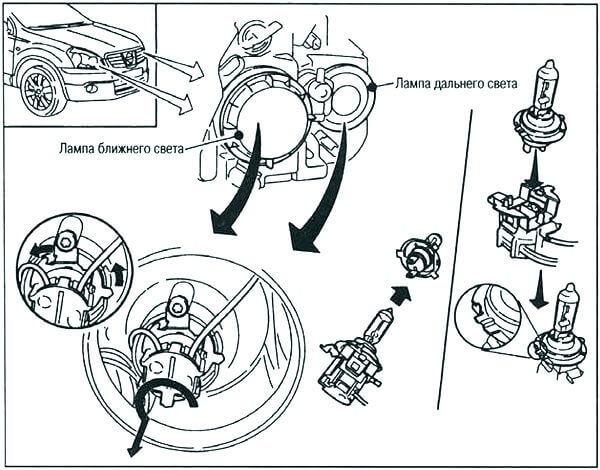

Iji dochie akara mmanụ ụgbọala gear, ị ga-:

- Kwupu kaadị cardan site na flange 14 (lee Fig 72) nke ogwe osisi;

- kpọghee ma wepụ nut 15, wepụ flange 14 na washer 16;

- kpọghee mkpụrụ osisi na-echekwa ihe mkpuchi igbe nri 13 wee jiri bolts na-ekpochapụ wepụ ihe mkpuchi igbe nri;

- dochie igbe nri, na-ejuputa oghere dị n'ime ya na griiz 1-13, ma kpokọta mgbakọ ahụ n'usoro ntụgharị (a na-agbanye igbe nri na-agbanye na njedebe mpụta nke mkpuchi).

Ọ bụrụ na ọ dị mkpa iji dochie igbe nri 9 (lee Fig 71), ogwe osisi axle ga-:

- kpochapu mmanụ site na crankcase nke àkwà mmiri ahụ site n'ịkpọpu mmiri na nkwụnye mmiri;

- gbanyụọ ogwe osisi cardan;

- wepụ obere mkpuchi 7 (lee Fig. 73) nke wheel gia;

- kpọghee nnukwu okpu fastening bolt 15 na, screwing ya n'ime threaded oghere na nsọtụ nke axle aro 22, jiri nlezianya wepụ ya ọnụ na anyanwụ gia 11 si wheel gia;

- Mepee mkpụrụ ndị ahụ site na studs na-echekwa igbe igbe etiti na igbe axle (ma e wezụga nke abụọ kachasị elu). Mgbe nke ahụ gasịrị, na-eji a trolley na a lift, wepụ gearbox, kpochie abụọ mbughari bolts n'ime gearbox flange na axle ụlọ, na mgbe wepụ ihe fọdụrụ abụọ elu mkpụrụ, dochie axle gearbox mmanụ akara na a puller, na-ejuputa n'ime oghere. na griiz 1-13.

A na-agbakọta axle azụ n'azụ azụ, na a ghaghị ịwụnye ogwe osisi axle nke ọma, na-atụgharị ya ka ọ ghara ịgbagọ egbugbere ọnụ akara.

A na-ejikọtakarị nrụzi akwa mmiri na mwepụ na mkpochapụ nke igbe etiti ma ọ bụ mbanye wheel.

Mwepụ nke Central gearbox MAZ

Tupu iwepu igbe etiti etiti, ọ dị mkpa ịkwanye mmanụ site na ụlọ axle, kwụpụ ogwe osisi cardan ma hapụ breeki na-adọba ụgbọala. Mgbe ahụ, wepụ obere ihe mkpuchi ihe mkpuchi wiil, kpochapụ nnukwu mkpuchi mkpuchi wheel na, na-atụgharị ya n'ụzọ ọzọ n'ime eriri eri na njedebe nke ọkpụkpụ axle, wepụ ihe ndị na-eme ka ọkpụkpụ si dị iche. Mepee studs na-echekwa igbe dị n'etiti na ụlọ axle wee wepụ igbe gear site na iji dolly.

A na-akpasa igbe etiti etiti nke ọma n'elu ugwu swivel. Na enweghị nkwado, enwere ike iji obere ọrụ na-arụ ọrụ dị elu nke 500-600 mm.

Usoro maka ịkwasa igbe gear bụ nke a:

- wepụ ihe mbanye ụgbọala 20 (lee Fig. 72) zuru ezu na bearings;

- wepụ mkpụrụ 29 na 3 site na mkpuchi dị iche iche;

- wepụ ihe mkpuchi dị iche iche 1;

- Kwụpụ mkpụrụ ndị ahụ site na studs nke iko dị iche iche ma mepee ihe dị iche iche (wepụ satellites, akụkụ gia, ịkwanye washers).

Saa akụkụ mpịachi nke igbe etiti wee lelee nke ọma. Lelee ọnọdụ nke bearings, n'elu arụ ọrụ nke na-ekwesịghị inwe spalling, cracks, dents, peeling, yana mbibi ma ọ bụ mmebi nke rollers na separators.

Mgbe ị na-enyocha gia, ṅaa ntị na enweghị ibe na nkwụsị nke ezé, mgbawa, ibe nke ciment oyi akwa n'elu ezé.

Site na mkpọtụ mkpọtụ nke gia nke etiti gearbox n'oge arụ ọrụ, uru nke mkpochapụ akụkụ nke 0,8 mm nwere ike bụrụ ihe ndabere maka dochie otu ụzọ bevel.

Ọ bụrụ na ọ dị mkpa, dochie ngwo bevel nke ịnya ụgbọ ala na a chụpụrụ dị ka ntọala, ebe ha na-adakọ na ụlọ ọrụ mmepụta ihe na ụzọ abụọ maka kọntaktị na mkpochapụ akụkụ ma nwee otu akara.

Mgbe ị na-enyocha akụkụ nke ihe dị iche iche, ṅaa ntị na ọnọdụ nke elu olu nke obe, oghere na mbara ihu nke satịlaịtị, ihe ndị na-ebupụta ihe dị n'akụkụ akụkụ, ndị na-ebu washers na njedebe njedebe nke iko dị iche iche, nke ga-abụ free nke burrs.

Ọ bụrụ na akwa akwa ma ọ bụ na-adịghị mma, dochie satịlaịtị satịlaịtị. A na-edozi ahịhịa ọhụrụ mgbe etinyere ya na satịlaịtị na dayameta nke 26 ^ + 0,045 mm.

N'iji ejiji dị ịrịba ama nke ndị na-ebu ọla kọpa nke osisi axle, a ghaghị dochie ha. Ọkpụrụkpụ nke ndị na-asa ọla ọla ọhụrụ bụ 1,5 mm. Mgbe ị na-achịkọta ihe dị iche iche, a na-atụ aro ka ịlele ọdịiche dị n'etiti gia n'akụkụ na ihe nkpuchi ọla na-akwado, nke kwesịrị ịdị n'etiti 0,5 na 1,3 mm. A na-atụle ọdịiche ahụ na ihe nlele mmetụta site na windo na iko dị iche iche, mgbe satịlaịtị na-agbaba n'ime ndị na-akwado nkwado ka ọ ghara ịdaba, na akụkụ nke akụkụ ahụ na-agbanye na satellites, ya bụ, ọ na-etinye aka na ha n'enweghị egwuregwu. A na-edochi iko dị iche iche dị ka nhazi.

Chịkọta igbe igbe etiti n'usoro a:

- chịkọta ihe eji akwọ ụgbọala, tinye ya n'ime ụlọ na-ebu ma dozie bearings tepeed na preload;

- chịkọta ihe dị iche iche, wụnye ya na crankcase ma dozie bearings dị iche na nke mbụ;

- wụnye draịva n'ime ụlọ gearbox;

- gbanwee njikọ aka nke bevel gia;

- gbanye ihe mgbochi gia na gia ruo mgbe ọ kwụsịrị, wee tọpụ ya site na 1 / 10-1 / 13 nke ntụgharị, nke kwekọrọ na ọdịiche dị n'etiti ha nke 0,15-0,2 mm, wee mee ka akụ mkpọchi sie ike.

Mwepu nke draịva wheel na mwepụ nke oghere azụ azụ

Usoro nkewasa bụ nke a:

- tọpụ mkpụrụ akụ na azụ ụkwụ;

- tinye jakị n'okpuru otu akụkụ nke azụ axle doo na

- kpọgidere bọket ahụ na wiil, wee tinye ya na nkwado ma wepụ jakị ahụ;

- kpọghee mkpụrụ ndị na-ejide azụ azụ, wepụ ihe mgbochi na wiil dị n'èzí, mgbanaka oghere na wiil dị n'ime;

- igbapu mmanụ site na wheel gia;

- wepụ nnukwu mkpuchi 14 (lee Fig 73) site na mgbakọ mbanye wheel na obere mkpuchi 7;

- wepụ ihe eji ebugharị 1, nke na-eji bolts abụọ site na nnukwu mkpuchi dị ka onye na-adọkpụ;

- sụọ ngọngọ nke nnukwu mkpuchi n'ime oghere eri nke ọkara ogwe 22, wepụ ọkara ogwe ya na gia etiti 11 n'ozuzu ya;

- Kpochapụ ihe mgbochi mkpọchi nke 3 axles site na satịlaịtị, wụnye ihe na-adọta ma wepụ axles nke satịlaịtị 5, wee wepụ satịlaịtị zuru oke na bearings;

- Kpupu nut mkpọchi 27 site na ebe a na-adọba ụgbọala, wepụ mgbanaka njide 26, wepụ nut 25 na bearings ma wepụ iko dị n'ime 21 na onye na-ebu ya;

- wepụ oghere nke na-ebu, wụnye hub puller ma wepụ mgbakọ hub na brum drum.

Mgbe ị na-edochi akara mmanụ na ihe mkpuchi, ị ga-:

- kpọghee breeki na-ekpudo bolts ma wepụ ihe mkpokọ uzuzu na mkpuchi igbe;

- wepụ igbe nri na mkpuchi ma wụnye igbe nri ọhụrụ nke nwere ọkụ ọkụ nke hama;

- N'iji ihe ndọta, dọpụta agbụrụ dị n'èzí na n'ime nke ihe nbibi wheel.

Sachaa oghere na akụkụ ihe eji eme wiil ma lelee ha nke ọma.

A naghị anabata ichichi oyi akwa carburizing n'elu ezé gia. Ọ bụrụ na enwere mgbawa ma ọ bụ ezé gbajiri agbaji, ekwesịrị dochie ngwo ahụ.

A na-eme ka ntinye nke nave na ntinye nke ụgbọala nke wiil na-eme ka ọ dị elu. N'okwu a, a ghaghị iburu n'uche na a na-emepụta ihe nkedo dị n'ime okpukpu abụọ na-eji ihe eji eme ihe n'ezie, nke a na-ahụ anya site na ntinye nke mgbanaka oghere. Na mgbakọ a, a na-akara akara na njedebe nke oghere na n'elu elu nke mgbanaka spacer. Ekwesịrị ịwụnye ihe mkpuchi a ka ọ bụrụ ihe zuru oke dịka akara ahụ siri dị.

A naghị anabata ngbanwe nke akụkụ nke ọ bụla nke ngwa ahụ, n'ihi na nke a na-agbanwe nkwụsị nke axial nke bear, nke na-eduga ná mbibi ya.

The hub bearings bụ adịghị mmezi, Otú ọ dị kwesịrị ekwesị hub alignment ka a na-ahụ n'anya site n'ịkwado n'ime agbụrụ nke ndị a bearings na anut na locknut. Ike a chọrọ iji mee ka akị na-ebu hub sie ike kwesịrị ịdị ihe dịka 80-100 n'arọ na mgbanaka nwere mgbanaka 500 mm.

Nlekọta nke azụ axle MAZ

Nlekọta nke azụ axle na-agụnye ịlele na idowe ọkwa mmanye achọrọ na igbe dị n'etiti na wheel wheel, ngbanwe nke mmanụ n'oge, ihicha oghere ventilashị, ịlele na ịgbatị ihe nkedo, na-elele mkpọtụ ọrụ na azụ axle okpomọkụ okpomọkụ.

Mgbe ị na-arụ ọrụ n'azụ axle, ekwesịrị ịkwụ ụgwọ nlebara anya pụrụ iche maka ịhazigharị igbe igbe etiti. A na-eme mgbanwe na-ewepụ igbe gearbox; N'okwu a, a na-ebu ụzọ gbanwee bearings tapered nke ụgbọala bevel na-akwọ ụgbọala na ihe dị iche iche, na mgbe ahụ, bevel na-agbanye n'akụkụ kọntaktị kọntaktị.

Ka ịgbanwee bearings nke mbanye bevel gear, ị ga-:

- kpowaa breeki na-adọba ụgbọala ma wepụ ihe mkpuchi caliper 9 (lee Fig. 72);

- igbapu mmanụ;

- unscrew the nuts on studs of the drive gear bearing home na iji mbughari bolts 27 wepụ ụlọ 9 na mbanye bevel gia mgbakọ;

- na-edozi crankcase 9 na osote, chọpụta nkwụsị nke axial nke bearings site na iji ihe ngosi;

- Mgbe ahapụchara crankcase 9, kpachie bevel gear na vise (dobe paịlị ọla dị nro na agba nke vise). Tọpụ ma wepụ flange nut 15, wepụ ihe ncha na flange. Wepu mkpuchi ahụ na kposara mbughari. Wepu onye na-atụgharị mmanụ 12, mgbanaka dị n'ime nke ihe n'ihu na igwe na-edozi 11;

- tụọ ọkpụrụkpụ nke igwe na-edozi ihe ma gbakọọ ihe uru ọ dị mkpa iji belata ya iji kpochapụ nkwụsị nke axial ma nweta ihe mbụ (mbelata nke ọkpụkpụ nke ihe nkpuchi ahụ kwesịrị ịdị nhata na nchikota nke nchikota axial shaft clearances na okwu. nke egosi na preload uru nke 0,03-0,05 mm;

- gwerie igwe na-edozi ahụ na uru achọrọ, wụnye ya na akụkụ ndị ọzọ, ma e wezụga maka mkpuchi 13 nwere akara mmanụ, nke a na-ekwesịghị itinye, ebe ọ bụ na esemokwu nke mkpuchi mmanụ megide n'olu nke flange agaghị ekwe ka nhazi ahụ mee ihe n'ụzọ ziri ezi. oge nke nguzogide mgbe ị na-atụgharị gia na bearings. Mgbe ị na-eme ka akị olu ahụ sie ike, gbanye ụlọ ndị na-ebu ibu ka e wee debe rollers nke ọma n'ọsọ ndị na-ebu;

- lelee ihe mbu nke bearings dabere n'ogo nke oge achọrọ iji tụgharịa ngwa mbanye, nke kwesịrị nhata 0,1-0,3 kgm. Nke a oge nwere ike kpebisie ike na-eji a torque wrench na nut 15 ma ọ bụ tụọ ike etinyere oghere na flange maka propeller aro arịọnụ bolts (Fig. 75). Ike etinyere perpendicular na radius nke oghere dị na flange kwesịrị ịdị n'etiti 1,3 na 3,9 n'arọ. Mara na ibu ibu ibu ibu na rola bearings ga-eme ka ha kpoo ọkụ wee daa ngwa ngwa. Na nkịtị ibu preload, wepụ aku si mbanye gia aro, na-ekiri ya ọnọdụ, na flange, wee tinyegharịa cover 13 (lee fig. 72) na gland na n'ikpeazụ kpọkọta mgbakọ.

A na-edozi njigide nke bearings dị iche iche site na iji mkpụrụ 3 na 29, nke a ga-agbanye n'ime otu omimi ahụ ka ọ ghara imebi ọnọdụ nke ngwa ahụ ruo mgbe a na-enweta preload achọrọ na bearings.

A na-ekpebi ibu ibu ibu site na ọnụọgụ nke achọrọ iji tụgharịa ihe dị iche, nke kwesịrị ịdị na oke nke 0,2-0,3 kgm (na-enweghị ngwa bevel). A na-ekpebi oge a site na mgbanaka torque ma ọ bụ site na ịlele ike etinyere na radius nke iko dị iche, ma hà nhata 2,3-3,5 n'arọ.

Osikapa. 75. Na-enyocha njigide nke ibu nke draịva gia nke igbe etiti

Usoro maka ịlele na ịhazigharị njikọ aka bevel gear bụ nke a:

- tupu wụnye crankcase, 9 bearings na ụgbọala gia n'ime gearbox ụlọ, kpoo ezé nke bevel gia na griiz atọ ma ọ bụ anọ ezé nke ụgbọala gia na mkpa oyi akwa nke agba n'elu ha dum;

- wụnye crankcase 9 na ngwa ụgbọala n'ime igbe igbe gearbox; kpochie mkpụrụ ahụ n'elu studs anọ gafere ma tụgharịa gia n'azụ flange 14 (n'otu akụkụ na nke ọzọ);

- dị ka akara (isi kọntaktị) nwetara na ezé nke ihe eji eme ihe (Table 7), ntinye aka ziri ezi nke ihe eji eme ihe na ọdịdị nke nhazi nhazi. Gear njikọ aka na-achịkwa site n'ịgbanwe ọnụ ọgụgụ nke spacers 18 n'okpuru flange nke mbanye gia na-ebu ụlọ na mkpụrụ 3 na 29, na-enweghị nsogbu mgbanwe nke dị iche iche bearings. Iji mee ka ụgbọala ahụ pụọ na ngwa a na-ebugharị, ọ dị mkpa idowe shims ọzọ n'okpuru crankcase flange, ma, ọ bụrụ na ọ dị mkpa, iji mee ka ihe ndị ahụ dị n'otu, wepụ shims.

A na-eji mkpụrụ 3 na 29 mee ihe iji mee ka ihe ndị a na-ebugharị ebugharị.

Mgbe ị na-edozi njigide (dị ka kọntaktị kọntaktị) na ezé gia, nọgide na-enwe ọdịiche dị n'akụkụ n'etiti ezé, uru nke maka otu ụzọ ọhụrụ kwesịrị ịdị na 0,2-0,5 microns. Mbelata nkwụsị n'akụkụ n'etiti ezé gia site na ịkwaga kọntaktị kọntaktị site na ọnọdụ a na-atụ aro ka anabataghị, n'ihi na nke a na-eduga ná mmebi nke njikọ ziri ezi nke gia na ngwa ngwa ha na-eyi.

Mgbe emezigharịrị njikọ aka ahụ, mechie studs niile na-echekwa ebe a na-ebu ibu na ụlọ gearbox, guzobe nkwụsị na mkpụrụ akụ, mechie njedebe 25 ruo mgbe enwere obere oghere nke 0 0,15-0,2 mm n'etiti cracker na ngwa a na-ebugharị. (a na-edobe oghere kacha nta site n'ịtụgharị gia nke ngwa a na-ebugharị kwa ntụgharị). Mgbe nke ahụ gasịrị, jiri akị mkpọchi kpochie ihe mgbochi gia 25.

Mgbe ị na-ewepụ igbe dị n'etiti site na ụgbọ ala (maka nhazi ma ọ bụ nrụzi), lelee ọdịiche dị n'etiti ụgbọ elu njedebe nke igbe igbe na nkwado nkwado, setịpụrụ na ụlọ ọrụ mmepụta ihe n'ime 0,5-1,3 mm.

A na-enyocha ọdịiche ahụ na ihe nlele mmetụta site na windo na iko dị iche iche, mgbe satịlaịtị na-agbaba n'ime ndị na-akwado nkwado ka ọ ghara ịdaba, na akụkụ nke akụkụ ahụ na-agbanye na satellites, ya bụ, ọ na-etinye aka na ha na-enweghị egwuregwu.

A na-egosi mmebi nke axle azụ na ụzọ isi kpochapụ ha na tebụl asatọ.

| Ọkwa nke patch kọntaktị na ngwa ebugharị | Otu esi enweta ezigbo gia | |

| Azu na azụ | ||

| Kọntaktị gia bevel ziri ezi | ||

| Bugharịa ngwo a na-ebugharị gaa na ngwa mbanye. Ọ bụrụ na nke a na-ebute nkwụsị nha nha gia dị ntakịrị, bugharịa ngwa draịva n'ime ngwa a chụpụrụ. | ||

| Bugharịa ngwo a chụpụrụ na ngwa mbanye. Ọ bụrụ na nke a na-ebute oke egwu eze gia, bugharịa ngwo ahụ gaa n'ọkwa ebugharị. | ||

| Bugharịa ngwo a na-ebugharị gaa na ngwa mbanye. Ọ bụrụ na n'otu oge ahụ ọ dị mkpa ịgbanwe azụ azụ na hitch, nyefee ngwo mbanye na ngwa a na-ebugharị. | ||

| Bugharịa ngwo a chụpụrụ na ngwa mbanye. Ọ bụrụ na nke a na-achọ ịgbanwe ihichapụ akụkụ na njigide, bugharịa ngwa mbanye pụọ na ngwa a chụpụrụ. | ||

| Bugharịa ngwa draịva ahụ gaa na ngwo ebugharị. Ọ bụrụ na mkpochapụ dị na njigide ahụ pere mpe, bugharịa ngwa a chụpụrụ na ngwa mbanye. | ||

| Bugharịa ngwa draịva ahụ pụọ na ngwa a chụpụrụ. Ọ bụrụ na egwu dị ukwuu, bugharịa ngwo a na-ebugharị gaa na gia ụgbọala. |

Gụọkwa nkọwapụta nke mmeri ZIL-131

| Ihe kpatara nsogbu | resource |

| Akwa kpo oku na-abawanye | |

| Oke ma ọ bụ ntakịrị mmanụ na crankcase | Lelee ma bulie ọkwa mmanụ dị na crankcase |

| Ngbanwe ngwa ngwa na-ezighi ezi | Hazie nhazi |

| Ọbara ibu ibu ibu | Gbanwee erughị ala |

| Mmụba mkpọtụ akwa mmiri | |

| Mmebi nke dabara na ntinye aka nke ngwa bevel | Hazie bevel gia |

| Ogwe aka tepeed eyighị ma ọ bụ nke na-ezighi ezi | Lelee ọnọdụ nke bearings, ọ bụrụ na ọ dị mkpa, dochie ha ma mezie tightness |

| Ike iyi akwa | Dochie gia eyi ma mezie nnyefe |

| Mmụba mkpọtụ nke àkwà mmiri okporo ụzọ na ntụgharị | |

| Mmejọ dị iche iche | Wepụ ihe dị iche na nchọpụta nsogbu |

| Mkpọtụ si n'ụgbọ ala niile | |

| Ngbanwe ngwa ngwa na-ezighi ezi | Dochie gia ma ọ bụ iko ebu. |

| Iji mmanụ mbanye wheel na-ezighi ezi | Mgbanwe mmanụ na crankcase flu |

| Ọkwa mmanụ ezughi oke | Tinye mmanụ na wheel wheel |

| Mwepu mmanụ site na akàrà | |

| Akara eyi ma ọ bụ mebie | Dochie akara |

Ngwaọrụ axle azụ MAZ

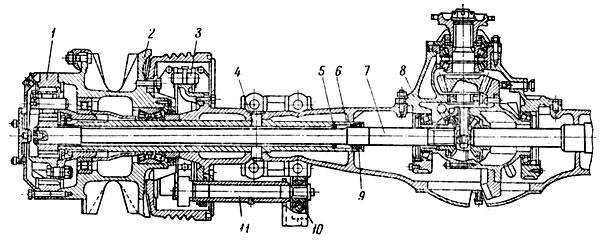

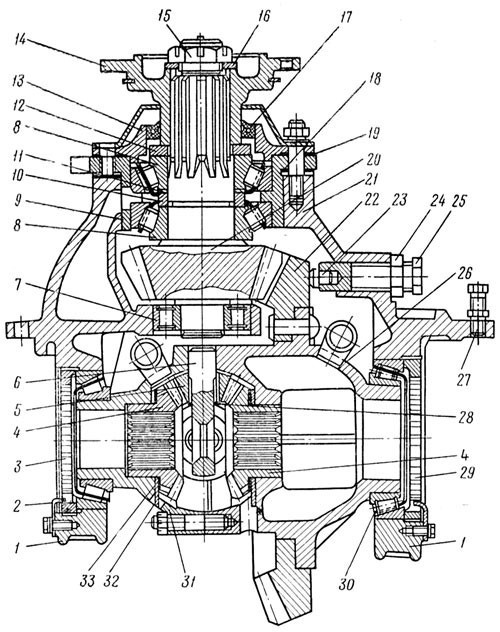

The azụ axle (Fig. 71) na-enyefe torque site na engine crankshaft site na njigide, gearbox na cardan shaft na-akwọ ụgbọala wiil nke ụgbọ ala na, na-eji ihe dị iche iche, na-ekwe ka ndị na-akwọ ụgbọala wiil na-agbagharị na dị iche iche angular ọsọ.

Osikapa. 71. N'azụ axle MAZ:

1 - akụrụngwa; 2 - oghere azụ azụ; 3 - breeki azụ azụ; 4 - mkpọchi ntụtụ nke ụlọ axle; 5 - mgbanaka nke axis na-eduzi; 6 - ụlọ axle; 7 - ogwe osisi axle; 8 - igbe igbe etiti; 9 - jikọtara epiploon nke a semiaxis; 10 - eriri ngbanwe; 11 - Kpuchie breeki aka

Atụmatụ nakweere na-ewuli elu na kinematic maka nnyefe torque na-eme ka o kwe omume kewaa ya n'ime igbe dị n'etiti, na-eduzi ya na igbe ọkpọ wheel, ma si otú a na-ebupụ ihe dị iche iche na axle site na ụbara torque, bụ nke a na-ebufe na atụmatụ abụọ site na. isi gia nke azụ axle (dị ka ihe atụ, ụgbọ ala MAZ-200). Ojiji nke sprockets na-enyekwa ohere, site n'ịgbanwe naanị ọnụ ọgụgụ nke ezé nke sprocket cylindrical gears na ịnọgide na-enwe ebe etiti nke sprockets, iji nweta ihe dị iche iche gia, nke na-eme ka azụ azụ dị mma maka iji mgbanwe ụgbọ ala dị iche iche.

The Central gearbox (Fig. 72) bụ otu-ogbo, mejupụtara otu ụzọ bevel gia na gburugburu ezé na ihe interwheel iche. A na-etinye akụkụ nke igbe gear na crankcase 21 nke ígwè ductile mere. A na-ekpebi ọnọdụ nke crankcase n'akụkụ osisi ahụ site n'ubu etiti na flange nke ụlọ gearbox yana mgbakwunye na atụdo.

The mbanye bevel gear 20, mere na otu ibe na aro, na-adịghị cantilevered, ma nwere, na mgbakwunye na abụọ n'ihu tapered roller bearings 8, ọzọ n'azụ nkwado, nke bụ a cylindrical roller bearing 7. The atọ-agba imewe bụ. kọmpat karịa, ebe oke radial dị na bearings na-ebelata nke ukwuu Tụnyere ntinye nke cantilever, ikike ibu na nkwụsi ike nke nrụnye bevel gear meshing na-abawanye, nke na-abawanye ogologo oge. N'otu oge ahụ, ohere nke ịbịaru nso na-agbagharị agbagharị agbagharị na okpueze nke bevel gia na-ebelata ogologo oge nke ogwe ya na, ya mere, na-enye ohere ịbawanye anya n'etiti flange na-ebelata na flange, nke dị ezigbo mkpa na obere obere. ụgbọ ala maka ebe ka mma nke ogwe osisi cardan. Ọsọ ndị dị n'èzí nke ndị na-agbagharị ihe na-agbagharị agbagharị dị na crankcase 9 ma na-agbanye na nkwụsị n'ime ubu mere na crankcase. A na-akụchi flange nke ụlọ ndị na-ebu ya na igbe axle azụ. Ihe mkpuchi ndị a na-eburu ibu radial na axial na-emepụta site na nchikota nke otu ụzọ bevel gia na nnyefe nke torque.

Osikapa. 72. Central gearbox MAZ:

1 - mkpuchi na-ebu; 2 - na-ebu mkpuchi nut; 3 - anut nke n'aka ekpe; 4 - ogwe osisi; 5 - satịlaịtị dị iche; 6 - obe dị iche iche; 7 - ibu cylindrical nke akụrụngwa ụgbọala; 8 - ihe eji akwọ ụgbọala conical; 9 - na-ebu ụlọ nke ụgbọala ụgbọala; 10 - mgbanaka oghere; 11 - nhazi ihe ncha; 12 - onye na-atụgharị mmanụ; 13 - mkpuchi igbe nri; 14 - flange; 15 - flange nut; 16 - ihe nchacha; 17 - igbe nri; 18 - osisi; 19 - gasket; 20 - ihe eji akwọ ụgbọala; 21 - igbe igbe; 22 - ihe eji eme ihe; 23 - kuki; 24 - akpọchi; 25 - onye na-amachi ihe eji eme ihe; 26 - iko dị iche iche ziri ezi; 27 - ihe mkpuchi nke mwepụ nke nnyefe; 28 - mkpali mgbanaka bushes; 29 - aku nke ibu nri; 30 - agba agba agba; 31 - otu iko nke ekpe dị iche iche; 32 - igwe nchara; 33 - ihe ncha ọla

Ihe nkedo dị n'ime nwere ihe dị nhịahụ na ogwe aka na mpụta nke dị n'elu nwere ihe nkedo na-adaba adaba iji kwe ka ngbanwe nke mbido na bearings ndị a. N'etiti mgbanaka dị n'ime nke ndị na-agbagharị ihe na-agbagharị agbagharị, a na-etinye mgbanaka spacer 10 na onye na-edozi ihe na-edozi 11. A na-ekpebi ihe mbụ achọrọ nke ihe nrịbama na-agbagharị agbagharị site na ịhọrọ oke nke igwe na-edozi ihe. A na-etinye cylindrical roller bearing 7 nke nnyefe bevel gear n'ime oghere tidal nke ụlọ axle gearbox n'akụkụ ebe a na-ebugharị ebugharị ma na-edozi ya site na mgbanaka axial na mgbanaka na-ejigide nke na-abanye na oghere n'ime ọhịa na njedebe nke ngwa ụgbọala.

N'ihu akụkụ nke ogwe nke bevel gear nke nnyefe, a na-egbutu eriri elu nke obere dayameta na spline nke nnukwu dayameta, nke a na-etinye mmanụ 12 na flange 14 nke ogwe osisi cardan. A na-eji nnukwu nut 15 mechie akụkụ niile dị na ogwe pinion.

Iji mee ka mwepụ nke ụlọ na-ebu ya dị mfe, flange ya nwere oghere eriri abụọ nke nwere ike ịkụnye eriri eriri n'ime ya; mgbe etinyere ya, bolts na-ezu ike megide ụlọ gearbox, n'ihi nke ụlọ na-ebu na-apụta na igbe igbe. Bolts nke otu ebumnuche, screwed n'ime flange nke gearbox ụlọ, nwere ike iji dị ka ikpochapụ bolts.

Ngwa bevel 22 agbagoro na iko dị iche nke ziri ezi. N'ihi mmachi dị n'etiti pinion na onye isi na ụlọ gearbox iji nye nkwado ọzọ maka gia azụ axle, rivets na-ejikọta gia na iko dị iche site n'ime na-aga n'ihu.

Ngwa a chụpụrụ agbadoro n'elu elu nke iko flange dị iche. N'oge a na-arụ ọrụ, enwere ike ịdọrọ ngwo a na-akpụ akpụ site na gia ụgbọala n'ihi nrụrụ, n'ihi nke a ga-agbajikwa njikọ gia. Iji belata nrụrụ akọwapụtara ma hụ na kọntaktị kwesịrị ekwesị na nchikota nke bevel gears, onye na-ebelata ihe nwere ihe mgbochi gia 25, nke emere n'ụdị bolt, na njedebe nke etinyere cracker brass. A na-agbanye ihe mgbochi ahụ n'ime ụlọ gearbox ruo mgbe nkwụsị ya na-emetụ ihu njedebe nke bevel bevel a na-ebugharị, mgbe nke ahụ gasịrị, a na-ewepụ ihe mgbochi ahụ iji mepụta nkwụsị dị mkpa na mkpụrụ akụ na-ekpochi.

Enwere ike idozi njikọ aka nke bevel gears nke draịva ikpeazụ site n'ịgbanwe setịpụ shims 18 nke ọkpụrụkpụ dị iche iche nke emere nchara dị nro ma tinye ya n'etiti ebe a na-ebu ibu na ebe obibi axle gearbox. A na-ahọrọ ụzọ abụọ bevel gia na ụlọ ọrụ mmepụta ihe (ahọpụtara) maka kọntaktị na mkpọtụ. Ya mere, mgbe dochie otu gia, ọzọ gia ga-dochiekwa.

The n'azụ axle di iche iche na-tapered, nwere anọ Satellites 5 na abụọ n'akụkụ gia 4. The Satellites na-n'ịnyịnya na elu-ike ígwè cross atụdo na okpomọkụ-emeso na elu hardness. Izi ezi nke imepụta obe 6 na-eme ka ọnọdụ ikwu ziri ezi nke satịlaịtị dị na ya na ntinye aka nke ọma na ngwa n'akụkụ. A na-akwado Satellites n'olu nke transom site na bushes mere nke ọtụtụ teepu ọla kọpa. N'etiti satịlaịtị na ntọala nke crossheads, a na-etinye mgbanaka ntinye ígwè 28, bụ nke na-edozi ohia nke satịlaịtị na nchekwa.

A na-atụba nsọtụ elu nke satịlaịtị dị n'akụkụ iko dị iche iche n'elu okirikiri. Nkwado nke satịlaịtị dị n'ime iko ahụ bụ igwe na-asa ọla kọpa, dịkwa okirikiri. Satịlaịtị ndị ahụ bụ ngwa bevel nke na-agba agba nke nwere nchara siri ike nke carburized alloy.

Ogwe obe nke nwere isi anọ na-abanye na oghere cylindrical kpụrụ n'ime ụgbọ elu nke iko na-ekewa n'oge nhazi nkwonkwo ha. Nhazi nkwonkwo nke iko na-eme ka a mata kpọmkwem ebe obe dị na ha. A na-enweta ebe etiti nke iko ndị ahụ site na ọnụnọ nke ubu na otu n'ime ha, na oghere ndị kwekọrọ na pin na nke ọzọ. A na-eji otu ọnụ ọgụgụ ahụ akara otu iko, nke ga-adabarịrị n'oge mgbakọ iji nọgide na-enwe izi ezi nke ebe oghere na ebe ndị e nwetara n'oge nhazi nkwonkwo. Ọ bụrụ na ọ dị mkpa iji dochie otu iko dị iche, nke abụọ, ya bụ zuru ezu, a ghaghị dochiekwa iko.

A na-eji ígwè ductile mee iko dị iche iche. N'ime oghere cylindrical nke oghere nke iko dị iche iche, a na-etinye gia ogologo-bevel ọkara-axial.

A na-eme ihe dị n'ime ime oghere nke oghere ọkara axial n'ụdị oghere nwere splines involute maka njikọ na ọkara axes. N'etiti ihe dị n'akụkụ akụkụ na iko ahụ enwere ohere kwekọrọ na ngbanwe nke strok sara mbara, nke dị mkpa iji dobe ihe nkiri mmanụ n'elu ha ma gbochie iyi nke ebe ndị a. Tụkwasị na nke ahụ, a na-etinye ihe nkpuchi abụọ n'etiti ebe ndị na-ebupụta nke njedebe nke semiaxes na iko: ígwè 32, ntụgharị a na-agbanwe agbanwe, na bronze 33, ụdị na-ese n'elu mmiri. Nke ikpeazụ dị n'etiti igwe nchara nchara na ihe n'akụkụ. A na-ejikọta paddles ndị ahụ na iko ndị dị iche iche, na-enye ụbara mmanu mmanu na akụkụ dị iche iche.

Ihe mkpuchi maka ọnọdụ ha ziri ezi gbasara ụlọ gearbox na-adabere na ya site n'enyemaka nke bushes na-edozi ya na studs. A na-ejikọta oghere crankcase na okpu ihe dị iche iche ọnụ.

A na-edozi preload nke roller bearings nke dị iche site na mkpụrụ 3 na 29. Na-edozi mkpụrụ nke ductile iron nwere turnkey protrusions n'elu cylindrical dị n'ime, nke a na-eji mkpụrụ osisi kpuchie ma dozie ya n'ọnọdụ a chọrọ na mkpuchi mkpuchi. 2, nke a na-ejikọta na igwe a na-emepụta n'ihu nke okpu na-ebu.

A na-agbanye akụkụ igbe gear mmanụ mmanụ nke mgbanaka mgbanaka nke ngwa bevel chụpụrụ. A na-awụsa akpa mmanụ n'ime ebe obibi gearbox, nke a na-awụpụ mmanụ a na-agbapụ na bevel gia, mmanụ na-agbadata na mgbidi nke ụlọ igbe gearbox na-edozi.

Site na akpa mmanụ, a na-enye mmanụ nri site na ọwa na ebe obibi pinion. Ubu nke ụlọ a na-ekewapụ bearings nwere oghere nke mmanụ na-esi na ya na-agbago ma na-agbagharị roller bearings. A na-eji mmanụ na-abata, na-agbapụta bearings, nke a na-etinye na cones n'ebe ibe ya nọ, na, n'ihi na-agbapụta ihe nke rollers conical, na-agbanye ya n'ụzọ dị iche iche: azụ azụ na-eweghachi mmanụ ahụ na crankcase, na n'ihu na-ebughachi ya. flange nke driveshaft.

Enwere mgbagha nchara siri ike siri ike n'etiti flange na ihe nbido. N'elu elu elu, onye na-asa ákwà nwere eriri aka ekpe nke nwere nnukwu ụda, ya bụ, ntụziaka nke eriri ahụ na-emegide ntụziaka nke ntụgharị nke gia; na mgbakwunye, a na-etinye onye na-asa ákwà na obere oghere na oghere nke igbe nri. Ihe a niile na-egbochi mmanụ mmanu ka ọ na-esi na ya pụta n'ime igbe nri n'ihi akara nke elu elu nke flange.

N'akụkụ flange, a na-eji mkpuchi nkedo na-emechi ụlọ ndị na-ebu ibu, nke a na-agbanye akwa gasket roba na-akwado onwe ya nke nwere akụkụ abụọ na-arụ ọrụ na-agbanye na njedebe mpụta. A na-eme oghere na ubu na-arị elu nke mkpuchi ahụ, na-adaba na oghere nwere mmasị na ụlọ ndị na-ebu. A na-etinye gasket n'etiti mkpuchi na ụlọ ndị na-ebu na wedges 18 n'ụzọ dị otú ahụ na nkwụsị nke dị n'ime ha na-adaba na oghere dị na mkpuchi na oghere dị n'ime ụlọ na-ebu, n'otu n'otu.

A na-eweghachi mmanụ dị ukwuu nke batara n'ime oghere nke mkpuchi ahụ na gearbox site na oghere dị na mkpuchi na valvụ na-achọsi ike n'ime ụlọ ndị na-ebu. A na-eji akụkụ ya na-arụ ọrụ na-arụ ọrụ na-agbanye akara rọba siri ike na nke a na-egbu maramara ma mee ka ọ dịkwuo elu n'elu flange 14, nke ejiri carbon ígwè mee.

Ihe nkedo gia cylindrical nke abụọ bụ naanị mmanye mmanye. A na-agba mmanụ ndị na-agbagharị agbagharị na iko dị iche iche n'otu ụzọ ahụ.

Ọnụnọ nke ngwongwo wiil, ọ bụ ezie na ọ na-ebelata ibu na akụkụ nke ọdịiche ahụ, ma dugara n'ịbawanye ọsọ ọsọ nke ntụgharị nke gia mgbe ọ na-atụgharị ma ọ bụ na-agbagharị ụgbọ ala. Ya mere, na mgbakwunye na ihe ndị a na-eme iji kpuchido esemokwu esemokwu (iwebata nkwado washers na bushings), a na-eme atụmatụ imezi usoro mmanye mmanye maka akụkụ dị iche iche. Akara agụba welded na iko dị iche iche were mmanu si na igbe gearbox wee duzie ya na akụkụ ndị dị na iko dị iche. Uba nke mmanu mmanu na-abata na-eme ka obi dị jụụ nke akụkụ nke rubbing, ntinye ha n'ime oghere, nke na-ebelata ohere nke ijide na eyi akụkụ.

Gụọ kwa Ndozi akụrụngwa KAMAZ

A na-etinye igbe igbe etiti a gbakọtara n'ụzọ zuru ezu n'ime nnukwu oghere dị n'ụlọ axle azụ wee jiri studs na mkpụrụ tinye ya n'ụgbọelu kwụ ọtọ. A na-eji gasket mechie flanges mating nke akụkụ etiti nke ụlọ axle azụ na igbe gear. N'azụ axle crankcase, oghere ndị a na-agbanye maka crankcase na-arị elu studs bụ ndị kpuru ìsì, nke na-eme ka njigide nke njikọ a dịkwuo mma.

A na-eji ígwè nkedo mee ụlọ axle azụ. Ọnụnọ nke oghere na ụgbọ elu kwụ ọtọ anaghị emetụta nkwụsi ike nke ụlọ axle azụ. Njikọ ya na gearbox siri ike ma ọ dịghị agbanwe n'oge ọrụ nke ụgbọ ala ahụ. Ịkwado dị otú ahụ na ụgbọ elu kwụ ọtọ nwere nnukwu uru ma e jiri ya tụnyere njikọ nke gearbox na ụlọ azụ axle na ụgbọ elu kwụ ọtọ, dịka ọmụmaatụ, na ụgbọ ala MAZ-200, ebe nrụrụ dị ukwuu nke oghere crankcase si n'elu mebie njikọ ya. na ụlọ axle azụ.

Ebe obibi axle azụ na-ejedebe na nsọtụ abụọ ahụ na flange nke ejiri breeki calipers nke azụ azụ na-agbaji. Site n'akụkụ elu, ikpo okwu mmiri na-ejikọta ya na ya n'ime otu dum, a na-emekwa tides na nyiwe ndị a site n'okpuru ebe a, nke bụ ntụziaka maka ubube azụ azụ na nkwado maka mkpụrụ nke ubube ndị a.

N'akụkụ ihe nkedo mmiri bụ obere ihe na-ejigide rọba. N'ime crankcase, a na-eme akụkụ abụọ n'akụkụ nke ọ bụla; n'ime oghere nke akụkụ ndị a nke njedebe cylindrical nke crankcase, a na-agbanye ha site na casing 6 (lee Fig 71) nke ogwe osisi axle 7.

Igbe Semi-axle n'ihi ọnụnọ nke wheel gia, na mgbakwunye na oge na-ehulata site na ike nke ibu ibu na ibu nke ụgbọ ala, na-kwajuru na a reactive oge chere site gia iko nke wiil. , nke a na-ejikọta ya na njedebe corrugated nke casing. N'akụkụ a, a na-etinye ihe ndị dị elu chọrọ na ike nke etiti ahụ. A na-eji tubing alloy nwere mgbidi nwere mgbidi na-eme ka ahụ ahụ ahụ nke a na-agwọta okpomọkụ maka ike dị ukwuu. Ike nrụgide nke ụlọ ahụ na ụlọ azụ azụ azụ ezughị iji gbochie ntụgharị ya, ya mere, a na-ekpochikwa ụlọ ahụ n'azụ ụlọ axle.

N'ime akụkụ crankcase dị nso na nyiwe mmiri, mgbe ịpịchara ahụ, a na-egwupụta oghere abụọ, n'otu oge na-agafe n'azụ ụlọ axle na ụlọ axle. Etinyere n'ime oghere ndị a bụ 4 nchara akpọchi ntụtụ welded na n'azụ axle ụlọ. Mkpọchi mkpọchi na-egbochi ahụ ka ọ na-atụgharị n'ime ụlọ axle azụ.

Ka ọ ghara imebi crankcase na ụlọ n'okpuru omume nke na-ehulata ibu na-ehulata, a na-etinye mkpọchi mkpọchi n'ime ụgbọ elu kwụ ọtọ.

Na nsọtụ mpụta nke crankcases nke ọkara axes, a na-egbutu splines na-enweghị usoro nke etinyere iko nke wheel wheel. N'otu akụkụ nke ahụ ahụ, a na-egbutu eri maka ịgbanye mkpụrụ nke ebe mgbaba wheel hub. A na-eme oghere maka mkpuchi mkpuchi 9 7 na ntuziaka centering mgbanaka 5 site na njedebe dị n'ime nke ụlọ ahụ. Akara akara bụ akara rọba abụọ dị iche iche na-agbachi onwe ha n'ime oghere nchara nwere akara na egbugbere ọnụ ha na-emechi ọnụ chere ibe ha ihu.

Ewezuga ohere nke ịba ụba nrụgide na cavities nke crankcases nke Central wheel Mbelata gia mgbe mmanụ na-ekpo ọkụ, atọ ventilashion valves na-arụnyere na elu akụkụ nke n'azụ axle ụlọ, otu n'akụkụ aka ekpe nke elu akụkụ nke elu. azụ axle, ọkara-axle ụlọ nke ọkara mgbasa na abụọ nso mmiri ebe. Mgbe nrụgide dị na oghere crankcase na-abawanye, valvụ ventilashị na-emeghe ma na-agwa oghere ndị a na ikuku.

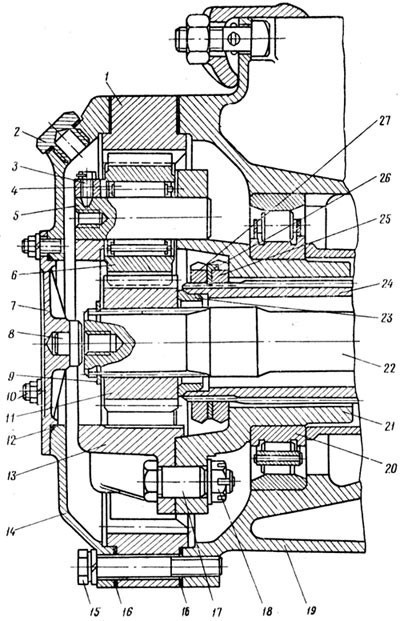

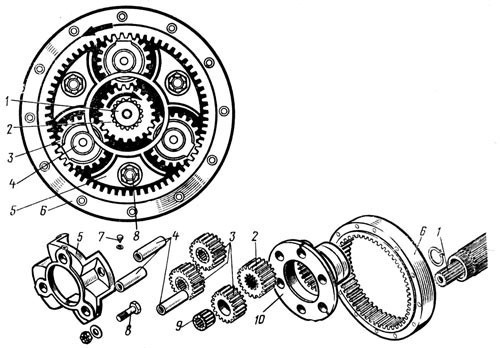

Ụgbọ ala (Fig 73) bụ ọkwa nke abụọ nke igbe igbe azụ azụ.

Site na ihe eji akwọ ụgbọ ala nke igbe dị n'etiti, site na bevel gear na-agba ọsọ na ihe dị iche iche, a na-ebufe torque na ogwe osisi axle 1 (Fig 74), nke na-enye oge ahụ na etiti etiti, nke a na-akpọ satellite 2 nke wheel. ịkwanye. Site na ngwa anyanwụ, a na-ebufe ntụgharị gaa na satịlaịtị atọ 3, na-agbatịkwa nke ọma gburugburu gburugburu ngwa anyanwụ.

Satellites na-atụgharị na axes 4, na-edozi n'ime oghere nke nkwado nkwado ahụ, nke gụnyere mpụga 5 na iko 10 nke dị n'ime, na ntụziaka na-abụghị ntụziaka nke ntụgharị nke ngwa anyanwụ. Site na satịlaịtị, a na-ebufe ntụgharị ahụ na mgbanaka mgbanaka 6 nke ihe eji eme ihe dị n'ime, na-agbanye n'elu oghere azụ azụ. Mgbanaka mgbanaka 6 na-atụgharị n'otu ụzọ ahụ dị ka satịlaịtị.

The gia ruru nke wheel mbanye kinematics atụmatụ kpebisiri ike site ruru nke ọnụ ọgụgụ nke ezé na mgbanaka gia na ọnụ ọgụgụ nke ezé na anyanwụ gia. Satellites, na-atụgharị kpamkpam na axles ha, anaghị emetụta ọnụ ọgụgụ gia, ya mere, site n'ịgbanwe ọnụ ọgụgụ nke ezé nke wheel wheel mgbe ha na-ejigide anya n'etiti axles, ị nwere ike nweta ọnụ ọgụgụ nke gia, nke, ọbụna na otu ihe ahụ. bevel gia na Central gearbox, nwere ike inye nnukwu gia ratio selectivity n'azụ akwa.

Osikapa. 73. Ụgbọ ala:

1 - mgbanaka mgbanaka (chụpụrụ); 2 - nkwụnye nkwụnye; 3 - njide nke axis nke satịlaịtị; 4 - usoro nke satịlaịtị; 5 - axis nke satịlaịtị; 5 - satịlaịtị; 7 - obere mkpuchi; 8 - mgbawa na-adịgide adịgide nke ogwe osisi axle; 9 - mgbanaka na-ejigide; 10 - ntutu isi; 11 - ngwa anyanwụ (na-eduga); 12 - mgbanaka akara; 13 - iko dị n'èzí; 14 - nnukwu mkpuchi; 15 - ihe mkpuchi nke nnukwu mkpuchi na ihe mgbanaka; 16 - gasket; 17 - otu iko nke mbido mmalite; 18 - aku; 19 - oghere wheel; 20 - mpụta nke oghere; 21 - iko ime chụpụrụ; 22 - ogwe osisi axle; 23 - nkwụsị ụgbọ ala; 24 - ụlọ axle; 2S - ehi na-ebu nut; 26 - mgbanaka ejigide; 27 - wheel na-ebu locknut

N'usoro, a na-eme ihe eji eme wheel dị ka ndị a. Ngwa niile bụ cylindrical, spur. Igwe anyanwụ 11 (lee fig 73) na satịlaịtị 6 - ihe eji eme ihe, okpueze - ihe eji eme ihe.

Ngwa anyanwụ nwere oghere nwere splines involute nke na-ejikọta ya na splines na njedebe kwekọrọ na ogwe axle. N'akụkụ dị n'ime ime ogwe osisi axle nwekwara splines gbagọrọ agbagọ nke jikọtara ya na splines dị n'ime oghere nke ogwe ndị dị iche. Ntugharị axial nke etiti etiti na oghere axle na-ejedebe site na mgbanaka na-ejigide mmiri 9. Ntugharị axial nke axle shaft 22 n'ebe etiti gearbox na-ejedebe site na etiti mbara ala dị na ya. N'akụkụ nke ọzọ, a na-egbochi mmegharị nke ogwe osisi axle site na mgbawa na-adịgide adịgide 8 na-agbanye n'ime ohia nke obere mkpuchi 7 nke wheel wheel. A na-atụkwasị Satellites n'elu osisi ndị edobere na nkwado mbughari nke nwere iko abụọ. A na-emepụta nnukwu efere dị n'ime 21 site na carbon steel, nwere oghere nke dị n'èzí yana oghere nwere oghere n'ime. Iko dị n'èzí 13 nwere nhazi dị mgbagwoju anya ma jiri ígwè nkedo mee ya. A na-ejikọta iko ndị na-ebu ibu site na bolts atọ.

Osikapa. 74. Atụmatụ ịkwọ ụgbọala na nkọwa ya:

1 - ogwe osisi axle; 2 - ngwa anyanwụ; 3 - satịlaịtị; 4 - axis nke satịlaịtị; 5 - iko mpụta; 6 - mgbanaka mgbanaka; 7 - njigide axis nke satịlaịtị; 8 - njikọ njikọ nke iko ebu; 9 - usoro nke satịlaịtị; 10 - ihe njide iko ime

N'ime iko ndị a na-agbakọta nke ụgbọelu ahụ, a na-edozi oghere atọ n'otu oge (gbapụtara) maka axis nke satịlaịtị, ebe ọ bụ na izi ezi nke ọnọdụ ikwu nke satịlaịtị n'ihe metụtara anyanwụ na mgbanaka mgbanaka na-ekpebi njide nnyefe ziri ezi, gia, na nakwa anwụ ngwa ngwa nke gia. Igwe igwe eji arụkọ ọrụ anaghị agbanwe agbanwe na ebe ndị ọzọ, ya mere ejiri akara akara. Akpa nke iko ndị dị n'èzí maka oghere axle satịlaịtị nwere oghere eriri maka mkpọchi mkpọchi nke axles satịlaịtị atọ.

A na-etinye ugogbe anya agbakọta (ihe njide ụkwụ) na akụkụ mpụta splined nke ụlọ axle. Tupu ị kụọ onye na-ebu ya, a na-etinye oghere wheel dị n'ime 19 na crankcase nke axle shaft na bearings abụọ. A na-etinye ihe mkpuchi mkpuchi okpukpu abụọ nke dị n'ime ozugbo na ụlọ axle, ebe a na-agbanye ihe mkpuchi cylindrical dị n'elu n'ụgbọ ụkwụ. A na-etinye ihe nkedo n'etiti ihe nkedo a na-agbanye okpukpu abụọ na ihe na-ebu wheel. Mgbe ahụ, a na-edozi ihe nkwado ahụ gbakọtara na ebe obibi axle na-eji nut 25 na mkpọchi 27. A na-etinye mgbanaka na-ejigide 26 n'etiti nut na mkpọchi nut, nke kwesịrị ịbanye n'ime oghere nke ụlọ axle na ntinye nke ime.

Iko ndị a na-agbakọta nke gia wheel na-etolite oghere atọ nke etinyere satịlaịtị n'ime ya. Satellites ejirila nlezianya rụpụta oghere cylindrical maka ntinye nke 4 cylindrical roller bearings nke na-enweghị mgbanaka mpụta ma ọ bụ n'ime. Ya mere, oghere cylindrical dị n'ime nke satịlaịtị bụ eriri knurling maka rollers nkwado. N'otu aka ahụ, elu nke satịlaịtị satịlaịtị na-arụ ọrụ nke mgbanaka dị n'ime nke ebu. Ebe ọ bụ na ịdịte aka nke bearings na-emetụta kpọmkwem na ike nke ụzọ agbụrụ, satịlaịtị satịlaịtị na-eji ígwè alloy na okpomọkụ na-emeso ya iji nweta ihe siri ike nke elu elu (HRC 60-64.

Mgbe ị na-agbakọta mbanye wiil, nke mbụ, a na-etinye bearings n'ime oghere nke satịlaịtị, mgbe ahụ, na-agbadata gia n'ime oghere nke iko ndị ahụ na-emepụta, a na-etinye eriri satịlaịtị n'ime oghere. A na-etinye eriri satịlaịtị n'ime iko ndị a na-emezigharị ma na-edozi n'ime ha site na ntụgharị na ntụgharị axial site n'enyemaka nke mkpọchi mkpọchi 3, mkpanaka conical nke na-abanye na oghere conical na njedebe nke satịlaịtị. Iji mee ka ọ dị mfe ịkwasa ogwe osisi a, enwere oghere eri n'ihu ya. Site n'itinye bolt n'ime oghere a site na aka uwe, na-adabere na iko dị n'èzí nke onye na-ebu ya, ị nwere ike wepụ ngwa ngwa site na satịlaịtị.

Ngwa ndị ahụ nwere ma ngwa anyanwụ na ngwa mgbanaka.

A na-ebufe Torque na gia isi site na ngwo atọ jikọtara ya, ya mere ezé nke mgbanaka mgbanaka na-adịchaghị ibu ma e jiri ya tụnyere ezé nke wheel wheel. Ahụmahụ ime ọrụ na-egosikwa na ijikọ gia na rim gia dị n'ime bụ nke kacha adịte aka. A na-etinye ihe mgbanaka mgbanaka na etiti ya na ubu n'ime oghere nke oghere azụ azụ. A na-etinye gasket n'etiti ngwa na oghere.

N'akụkụ dị n'èzí, n'etiti etiti olu nke mgbanaka mgbanaka, e nwere nnukwu mkpuchi 14 nke na-ekpuchi ngwa ahụ. A na-etinyekwa gasket mkpuchi n'etiti mkpuchi na ngwa. A na-eji mkpuchi na-ejikọta ihe mkpuchi na mgbanaka mgbanaka ahụ site na 15 ruo n'azụ azụ azụ, nke a na-agbanye n'elu ebe a na-agbanye n'elu wheel wheel, na-enye nkwekọrịta dị mkpa nke ọnọdụ nke satellites na nkwado na axle, nkenke oghere. nke otu ụgbọelu na-etinye n'oge machining na njikọ ziri ezi nke Satellites na clockwork isi. N'aka nke ọzọ, anyanwụ gia enweghị nkwado pụrụ iche, ya bụ, ọ "na-ese n'elu" ma na-adabere na mbara ala gia ezé, ya mere ibu na mbara ala gia bụ itule, ebe ọ bụ na ha na-evenly spaced gburugburu gburugburu na zuru ezu ziri ezi. .

The anyanwụ gia nke wheel mbanye na Satellites na-mere nke elu mma alloy ígwè 20ХНЗА na okpomọkụ ọgwụgwọ. Isi ike nke ezé gia erute HRC 58-62, na isi nke ezé na-anọgide ductile na ike nke HRC 28-40. Ngwa mgbanaka a na-ebuchaghị ibu bụ nke ígwè 18KhGT.

A na-agbanye gia na bearings nke gia mbelata wheel na mmanụ ịgbasa n'ime oghere nke ihe mbelata wheel. N'ihi na ụlọ ihe eji eme ihe nwere nnukwu mkpuchi na oghere azụ azụ nke na-agbagharị na ebe a na-agbagharị agbagharị, mmanụ dị n'ime ụlọ a na-eme ka ọ na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ mmanye na ngwongwo niile. A na-awụsa mmanụ site na obere okpu 7, nke a na-etinye na nnukwu wheel mbanye nwere ntụtụ atọ wee mechie ya n'olu etiti yana mgbanaka mkpuchi rọba 12.

Na obere mkpuchi ahụ wepụrụ, ọnụ ala nke oghere dị na nnukwu mkpuchi na-ekpebi ọkwa mmanụ achọrọ na ụgbọ okporo ígwè wheel. Nnukwu mkpọpu mmanụ nwere oghere mechiri ya na plọg gbọmgbọm. Iji gbochie mmanụ ka ọ na-esi na oghere nke wheel wheel banye n'ime igbe dị n'etiti, dị ka e kwuru n'elu, a na-etinye akara mmanụ okpukpu abụọ na ogwe osisi axle.

Mmanụ si n'oghere mbanye wheel na-abanyekwa n'ime oghere oghere azụ azụ iji mee ka mmanu nke wiil ndị nwere tapered okpukpu abụọ na cylindrical.

Site n'akụkụ dị n'ime nke oghere ahụ ruo n'ihu njedebe ya, site na gasket roba, a na-ekpuchi ihe mkpuchi igbe nri, nke a na-etinye igbe na-ekpochi roba-metal onwe onye. Ọnụ na-arụ ọrụ nke igbe nri na-emechi oghere nke oghere ahụ n'akụkụ mgbanaka mbughari nke a na-agbanye n'ime ụlọ axle. Elu nke mgbanaka na-agbada n'ogo dị elu nke ịdị ọcha, na-esi ike dị elu ma na-egbuke egbuke. Ihe mkpuchi igbe nri na oghere wiil na-adabere n'ubu, nke n'otu oge ahụ na-adabere na mgbanaka dị n'elu nke okpukpu abụọ, na-egbochi mmegharị axial ya.

N'ime mkpuchi gland, flange, nke buru ibu buru ibu, na-eje ozi dị ka onye na-atụgharị mmanụ, ebe ọ bụ na e nwere obere oghere n'etiti ya na mgbanaka gland nke mbughari. Ọzọkwa, n'elu cylindrical nke flange, a na-egbutu oghere ndị na-agbapụta mmanụ, na-enwe mmasị na ntụziaka nke na-abụghị ntụziaka nke ntụgharị nke oghere. Iji gbochie griiz ịbanye n'ụgbọ mmiri breeki, a na-eji ihe nkpuchi mmanụ mechie akara mmanụ.